PVC Tarpaulin for Agriculture..

- 2025-12-17

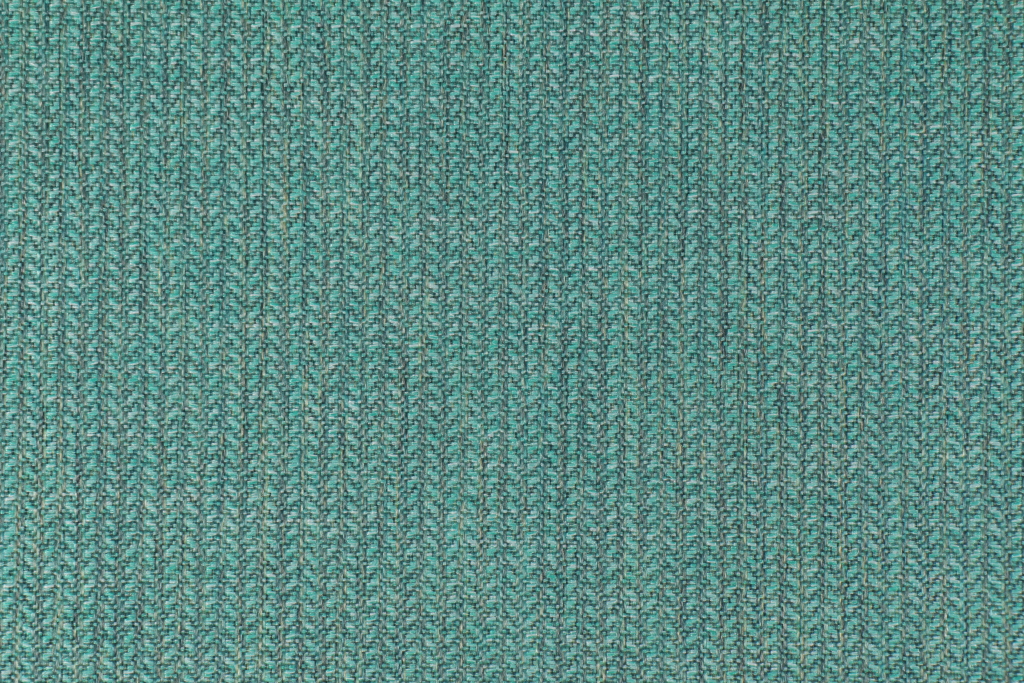

Olefin (polypropylene) fabrics are made of synthetic fibers that are durable and stain resistant.

To learn more in depth, visit our What exactly is Olefin blog.

In Italy during the 1950's, chemist Giulio Natta, developed a process that made Olefin suitable for a variety of textile applications.

In 1960, the United States began producing the fiber. Today, Olefin makes up 16% of the total fiber production in the US. Predominately, you can find Olefin fibers in upholstery fabric.

Olefin is difficult to dye once it has been formed.

Since Olefin fibers are tough to dye after manufacturing, it is solution-dyed.

The colors are added into to the polymers before or during melting.

The melted polymer is then spun by a spinneret, which looks a little bit like a shower head.

The fiber is pulled through tiny holes to form long fibers.

What is Olefin Fabric Used for?

The many benefits of olefin mean that is used for a wide variety of purposes.

One popular use in outdoor furniture.

This includes outdoor patio furniture cushions, outdoor rugs, outdoor bean bag chairs, and throw pillows.

The fabric’s water resistance, stain resistance, and fade resistance mean that it can stand up to rain, dirt, and sunlight over time.

Another popular use for olefin fabric is in automotive interiors.

The fabric won’t puncture or wear easily when passengers slide in and out of the car.

Stains won’t stick, and your seats will be easy to clean.

Upholstery and wall-coverings can also be made from olefin.

The patterns and colours won’t fade in the light or wear in spots where people sit or frequently brush against them.

Olefin is also used for a variety of industrial purposes.

This includes use for filters, bags, and geotextiles.

Not all olefin fabrics are created equal.

If you want to enjoy the many, many benefits of olefin materials,you’ll want to choose a high-quality product.

When you’re shopping for olefin fabrics, make sure that you choose items with a tight weave.

A loose weave may negate some of the fabric’s benefits, like strength.

Besides a tight weave, fabric that has been properly dyed is also a must.

This will help ensure that it doesn’t fade over time, losing it’s bright, vibrant look.

Another thing to consider when choosing a product made with the use of olefin is whether it is designed for outdoor use.

Basic olefin fabric on its own is not designed for use outdoors.

This means that bright colours and punchy patterns may quickly fade, as the fabric is quite sensitive to sunlight.

However, olefin is incredibly popular for outdoor use.

It is so easy to clean, lightweight, and resistant to bugs and mildew.

All of these qualities make it ideal for outdoor use; except for its susceptibility to fading in the sun.

For that reason, manufacturers have engineered new olefin fabric that is resistant to sunlight.

All you have to do is ensure that you’re choosing the right olefin fabric for your outdoor patio cushions, throw pillows, curtains, and other fabric products.

Caring for Olefin Fabric

While olefin fabric is resistant to moisture, stains, mould, punctures, and more, that doesn’t mean that it is completely maintenance-free.

Olefin is great for use in many different environments, but it is also heat sensitive.

You won’t want to expose your fabric to extremely high temperatures or else it may melt.

Most households won’t run into this issue very often, but it is something to consider when olefin is used in industrial environments.

One instance when you will want to be careful about the heat in your house is if you ever need to iron your olefin fabric.

If you must use an iron, set it on the lowest temperature setting that you can.

The second instance when you may find yourself accidentally exposing your olefin material to heat is in the wash.

If you need to wash your olefin and dry it afterwards, set your dryer to tumble dry with gentle or no heat. If you can, it’s best to hang the fabric to dry instead.

Choosing Your Olefin Products

Olefin is a great choice for everything from outdoor bean bags to automotive interiors.

Durable and long-lasting, it will help you create bright, beautiful lounge spaces that you’ll enjoy for years to come.

How Is Olefin Produced? How are the fibers made?

The process used to produce olefin is a far cry from wool sheared from sheep or cotton grown, picked, and processed.

Because olefin is derived from chemicals, producing it involves a complicated chemical process.

To start, the chemicals used to produce olefin, including propylene and ethylene, are melted down.

These chemicals require a temperature of between 110 degrees Celsius and 135 degrees Celsius to melt.

Once they are melted, they are fed through a device known as a spinneret.

A spinneret is a large device that looks similar to a showerhead. It contains small holes that the melted chemicals are forced through.

The melted chemicals now form long fibres that are then allowed to dry.

Once dry, they can then be woven into the fabric form of olefin that is used to create products like cushions and pillows.

But before olefin can be used to produce consumer products, it needs to be dyed.

Olefin fabric, once it is woven, is very tough to dye.

Instead, the chemicals used to produce olefin are dyed long before they are made into fibres and woven.

This is done by using a solution dye that is added directly to the chemicals before they are melted.

Sometimes the solution dye is added while the chemicals are being melted down and mixed.

It’s the Eco-Friendly Choice

One of the biggest benefits of olefin is how eco-friendly it is.

Compared to cotton, which is grown, or wool, which is sheered from sheep, the chemical process used to create olefin may sound like the furthest thing from eco-friendly.

But the reality is that the production process involves very little by-product.

This means that the ingredients used to create the fabric are completely used. Nothing needs to be thrown away, recycled, or processed.

Another reason why olefin is so eco-friendly is the ability to reuse the fabric.

Once a product created from olefin is no longer needed, begins to tear, or has otherwise begun to wear out, it can be broken down, back to its original fibres.

These fibres can then be rewoven to create brand new olefin fabric.

In fact, olefin is so reusable that its fibres can be recycled and re-extruded up to 10 times before it is no longer usable.

There are several benefits of this process. One, is the manufacturing process is less expensive than others.

Manufacturing Olefin produces very little by-product; that means less waste, which is good for the environment. Olefin fibers are plastic and 100% recyclable.

Olefin fabric has many advantages:

These fabrics are extremely durable.

Spills and stains are easy to clean.

Stain resistance and durability are a huge benefit if you have pets or children in your home.

The fabric is even bleach safe for tough stains!

Olefin is resistant to abrasion and mold.

It does not absorb water. Waterborne stains are not a problem.

It comes in a variety of colors and will not fade.

You can find olefin fibers in car and upholstery fabrics, carpets, clothing as well as rope.

So there's nothing wrong with Olefin Fabrics?

I would love to say “yes”, but nothing is perfect! Oil bonds with Olefin. Oil-based stains are tough to remove.

Olefin can break down if extreme heat is applied to the fabric.

This would only be a problem if you used a high setting on an iron or a high temperature to dry it.

For items that need a fire retardant treatment (FR), Olefin wouldn’t work.

How is it cleaned?

Most stains can be easily removed by dabbing the stain with lukewarm water and a mild detergent.

You can use bleach on Olefin fabric if necessary.

If you wash Olefin, line drying is the best option.

If you put the fabric in the dryer use a low heat setting.

Ironing the fabric is not recommended.

Do not use a brush. Do not dry clean, as many dry-cleaning solvents can harm the fibers.

Usage for Olefin outdoor fabric::Pillows,Table Top,Bags, Purses & Totes

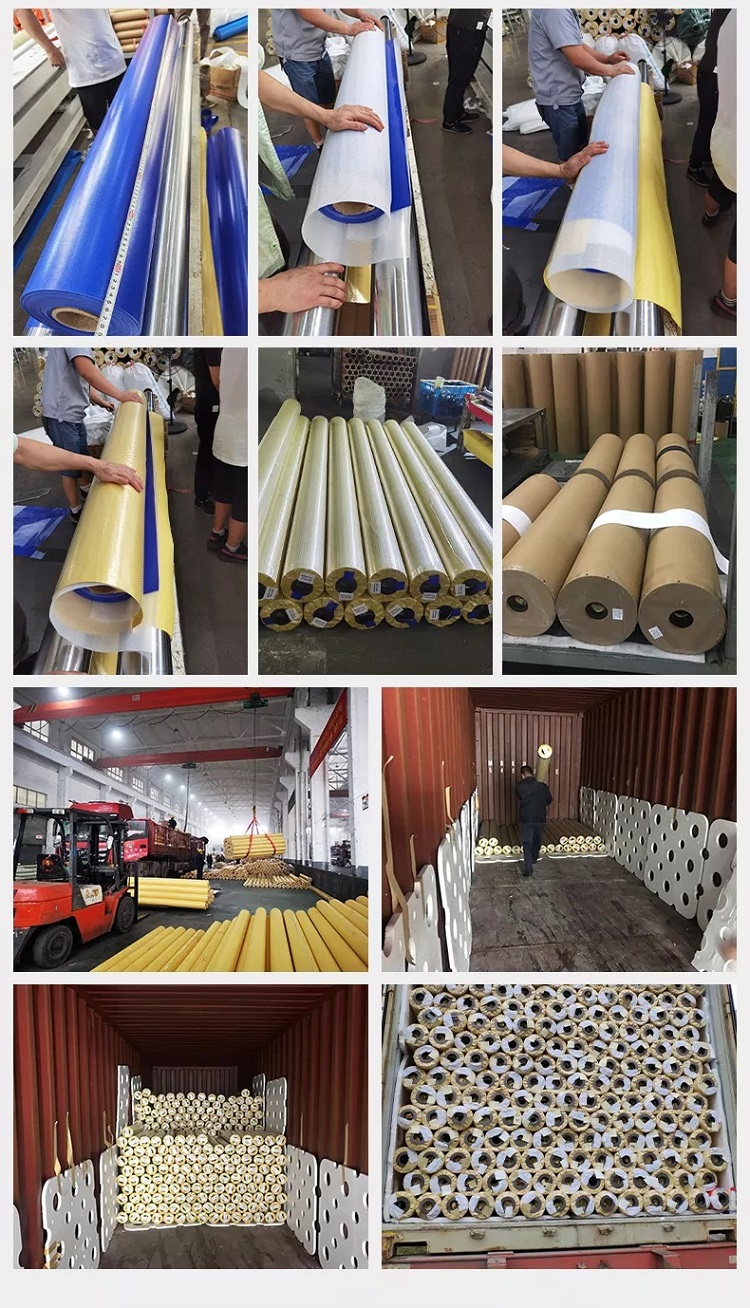

Shipping:

*We can typically ship same or next day when payment is received

*We will neatly fold and place the item in a box for shipping.

If you like it to be in roll form please let us know and we will calculate shipping fees accordingly.

*We can also combine shipping to help you save even farther

Payment:

We accept payment in the form of:

Paypal & Credit Cards

Returns:

Each yard of material must be cut from the roll therefore we do not offer returns or exchanges,

but if for any reason you are not happy with what you have received please contact us asap as we will handle any problems for you to insure your full satisfaction.

Contact:

Email: grace@der-factory.com

WhatsApp:+8615721533796

WeChat:+8615721533796

Phone Number:+8615721533796

Webiste: www.der-factory.com

*Please feel free to contact us at any time for questions or more details about any of our items.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.