PVC Tarpaulin for Agriculture..

- 2025-12-17

I. Product Introduction

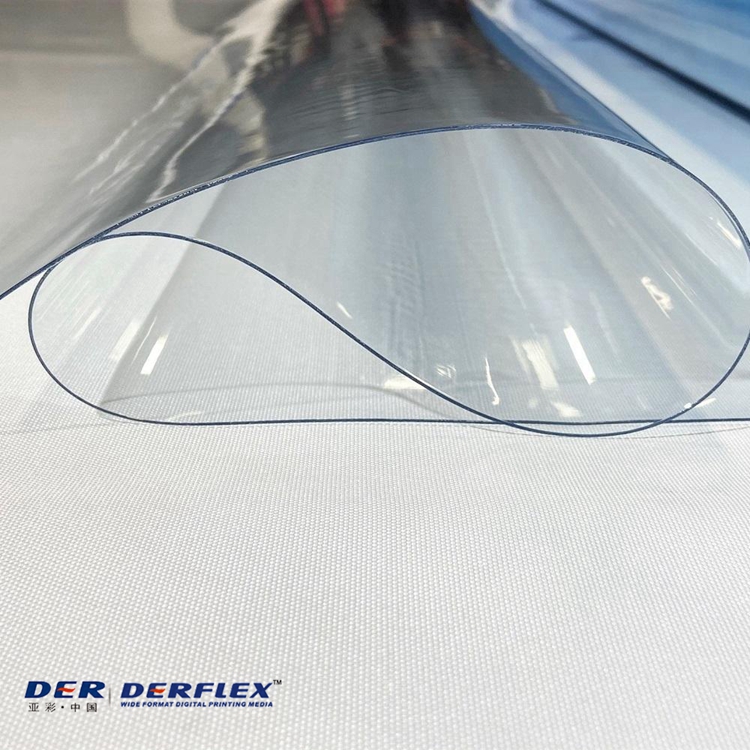

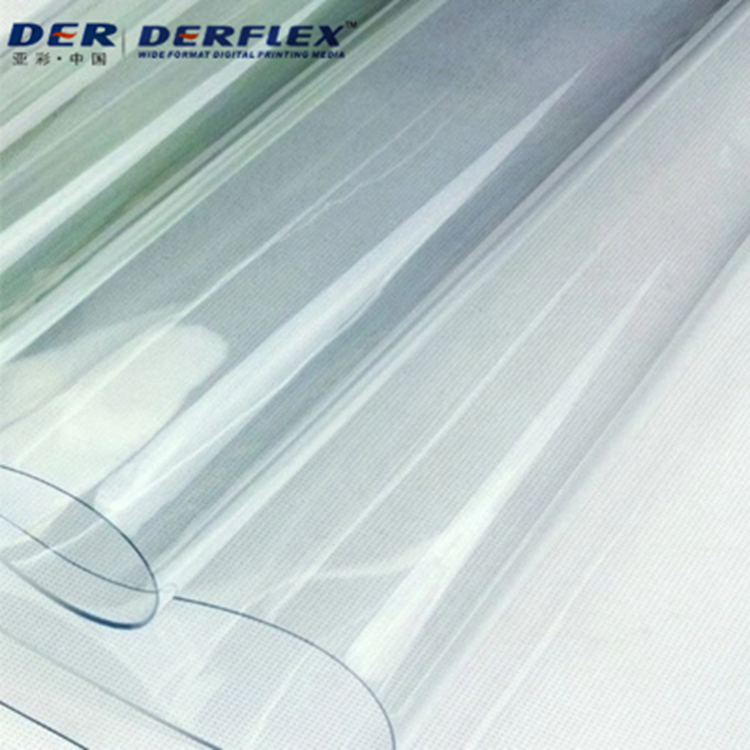

Introduction to PVC Ultra-Transparent Materials

Material Composition

PVC (polyvinyl chloride) ultra-transparent materials are mainly made of PVC resin, plasticizer, stabilizer, filler, lubricant, slip powder, etc. mixed in a certain proportion. These ingredients are carefully proportioned to ensure that the PVC material has other required physical and chemical properties while maintaining high transparency.

Production Process

Ingredients: PVC resin, plasticizer, stabilizer, filler, lubricant, slip powder and other raw materials are mixed in a certain proportion to form a PVC composite material.

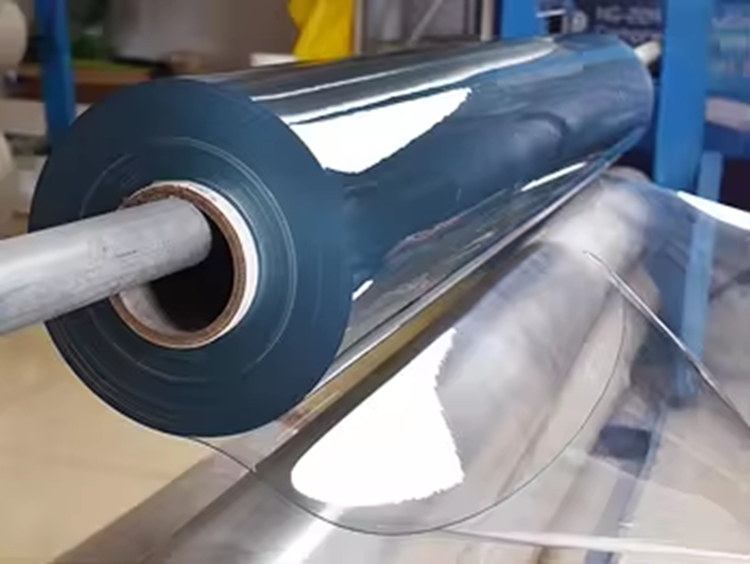

Melt extrusion: The PVC composite material after ingredient treatment is heated to a molten state and extruded through an extruder to form a continuous PVC film or sheet.

Film/sheet stretching: For PVC film, the extruded film is cooled and stretched horizontally and longitudinally on a stretching machine to change the film tension and size and improve the tear resistance. For PVC sheets, similar stretching or calendering processes may be required to adjust the size and performance of the sheet.

Cooling and curing: Place the stretched PVC film or sheet in a cooling device and cool it down and cure it by natural cooling or external water cooling to obtain the required hardness and stability.

II. Product Information

Product Name: PVC Ultra-transparent Film

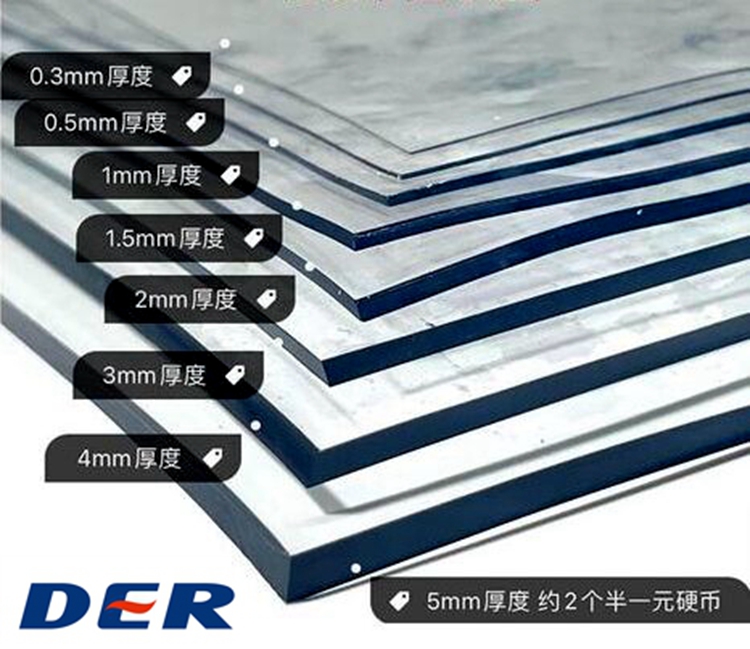

Product Thickness: 0.3-4MM

Product Width: Maximum 2M

Product Color: Customizable

Product Hardness: Customizable

Product Features:

High Transparency: PVC transparent material has good transparency and can provide clear visual effects, making it widely used in many fields.

Good Weather Resistance: PVC transparent material can maintain stable physical properties under various climatic conditions, and is not easy to deform, age, crack, etc.

Good Chemical Resistance: PVC transparent material can withstand the corrosion of a variety of chemical substances and is suitable for special environments such as chemical plants, laboratories, etc.

Good Flame Retardant Performance: PVC transparent material has good flame retardant performance, can self-extinguish, is not easy to burn, and effectively protects personal safety.

Good Processing Performance: PVC transparent material is easy to process into various shapes and sizes to meet the design requirements of different needs.

Low Cost: Compared with other materials, the production cost of PVC transparent material is relatively low, and it has certain economic advantages.

Good Environmental Performance: PVC transparent material does not contain harmful substances, meets health and safety standards, can be recycled and reused, and reduces resource consumption and environmental pollution.

III. Product Use

Advertising and Promotional Display: Utilize the high transparency and bright colors of PVC transparent materials to make various billboards, display racks, etc. to enhance the publicity effect.

Packaging Materials: PVC transparent materials can be used to make various packaging films, packaging bags, etc. to protect the safety and hygiene of goods during transportation and storage.

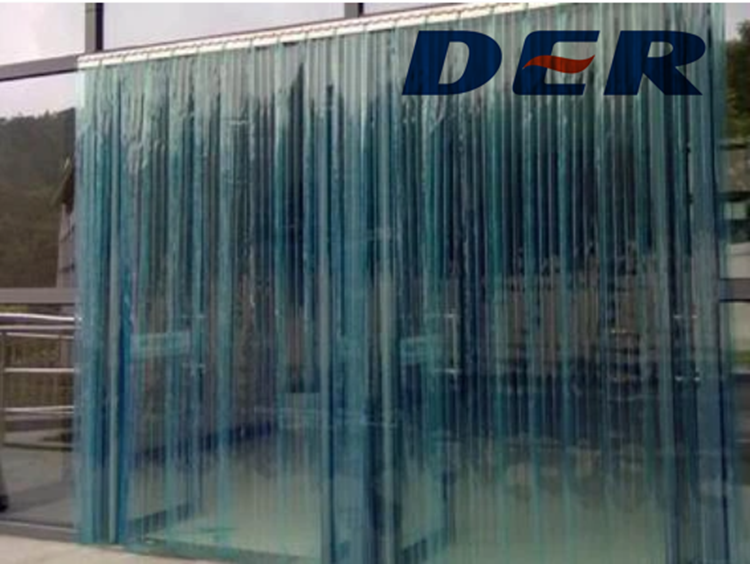

Building Materials: PVC transparent materials can be used to make building materials such as windows, partitions, and awnings, with good waterproof, windproof, and heat-insulating properties.

Household Supplies: PVC transparent materials can be used to make furniture, decorative panels and other household items to enhance the beauty and practicality of the home.

Medical Field: PVC transparent materials can be used to make medical supplies such as protective clothing, isolation curtains, etc., with the characteristics of waterproof, oil-proof, and anti-bacterial infection.

Industrial Protection: PVC transparent materials can be used to make protective covers for industrial equipment and safety protection supplies for operators to protect workers from splashes, chemicals, etc.

IV. Company Profile

Anhui Yaen New Materials Co., Ltd. is one of the leading heavy-duty PVC coated tarpaulin manufacturers in China with more than 20 years of experience. We have been committed to the research, development and manufacture of tarpaulin products since 1997. We have a large number of advanced equipment, scientific management, first-class technology, continuous design and professional team to meet market needs in a timely manner. As a professional PVC tarpaulin manufacturer with more than 20 years of production and sales experience. We have 2 knife coating production lines, 4 calenders, 8 laminating machines, producing double-layer and coated PVC tarpaulin materials for various fields. We are a high-tech industrial company certified by Zhejiang and Anhui provinces, and have won the National Technology Progress Award. Now, we have 8 doctors, 23 postgraduates and many employees with bachelor's degrees to improve and develop new products and production processes, which ensures DER as a developing coated fabric company.

Elaine Zhang销售经理

Tel:+86 199 5504 7834(wechat/whatsapp)

E-mail: elaine@der-factory.com

Web: www.der-factory.com/en

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.

Message