PVC Tarpaulin for Agriculture..

- 2025-12-17

DER New Material manufactures premium custom tarps and made-to-order tarpaulins to meet specialized needs: printed branding, reinforced edges, custom sizes, color-matched rolls, and industry-grade coatings for long-lasting outdoor protection. Request bespoke quotes and samples for any volume — from single prototypes to full container loads.

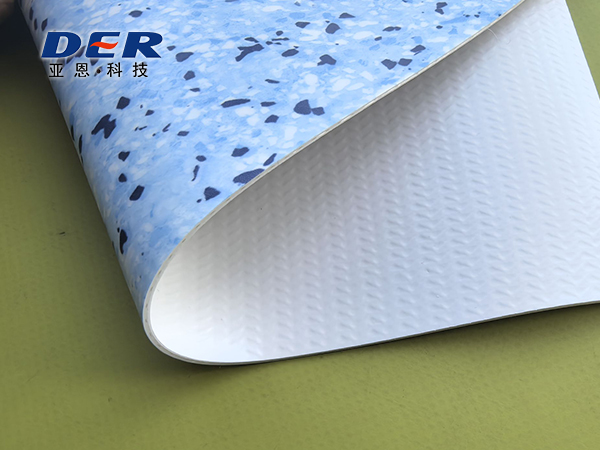

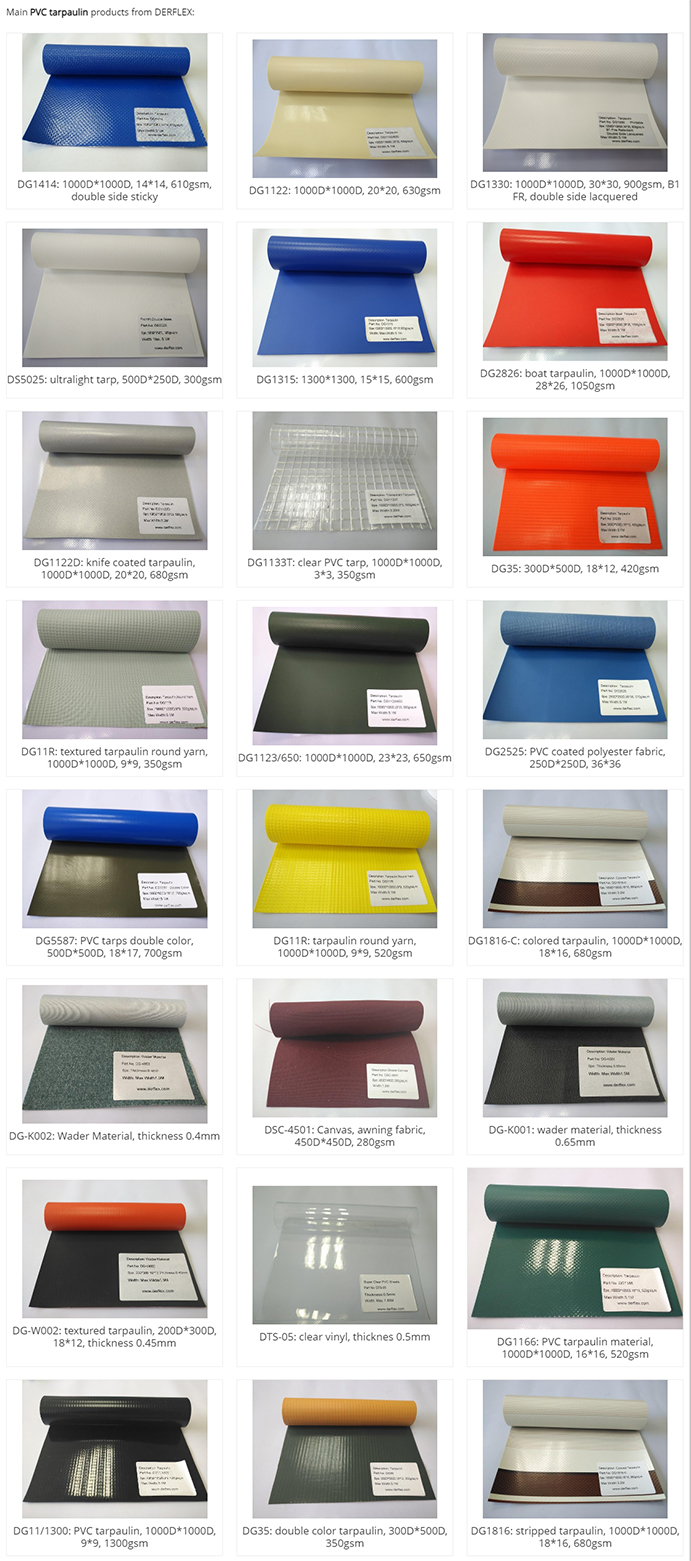

“Custom tarps” refers to tarpaulin products manufactured to your exact specifications rather than off-the-shelf sizes. Custom options include tailor-cut dimensions, bespoke weights (GSM), printed logos and artwork, reinforced hems and edges, special eyelet spacing, welded seams, welded pockets, multiple fabric choices (PVC coated polyester, PE laminated fabric, TPU, or specialty technical textiles), and functional finishes (UV inhibitors, anti-mildew treatment, flame retardants, anti-slip surfaces, and food-grade coatings). At DER New Material we combine design support, CAD cutting files, and industrial finishing to deliver repeatable, reliable custom tarpaulin products for every sector.

DER New Material specializes in both laminated and coated constructions: hot-melt laminated PVC tarpaulins for economical durability, and coated PVC for premium flexibility and adhesion. For less permanent or lighter-duty projects we also offer PE laminated tarps. All custom tarps are available in continuous rolls (widths up to 5.10m), cut-sheet formats, or as finished sewn/welded tarpaulins with added fittings.

When clients ask for custom tarps, they typically need a combination of performance and specific fit. Our custom tarpaulin features include:

| Parameter | Range / Options |

|---|---|

| Base Fabric | Polyester 300D – 1000D; HDPE / LDPE woven for PE tarps |

| Coating Type | PVC single/double-side coated, PE laminated, TPU coated |

| Weight | 300gsm – 1200gsm (custom) |

| Thickness | 0.25mm – 1.2mm |

| Widths | Standard up to 5.10m (continuous roll); custom seams for wider spans |

| Color | Any Pantone-matched color (MOQ may apply) |

| Printing | Digital/Rotogravure up to 6 colors; UV-stable inks |

| Eyelets | Brass / Stainless steel / Plastic; spacing per customer (e.g., 25–100cm) |

| Seams | Hot-wedge or ultrasonic welding; sewn with reinforced tape |

| Reinforcements | Corner plates, rope hems, webbing straps, load-lifting pockets |

| Certifications Available | ISO9001, SGS reports, RoHS/REACH, Fire retardancy test (on request) |

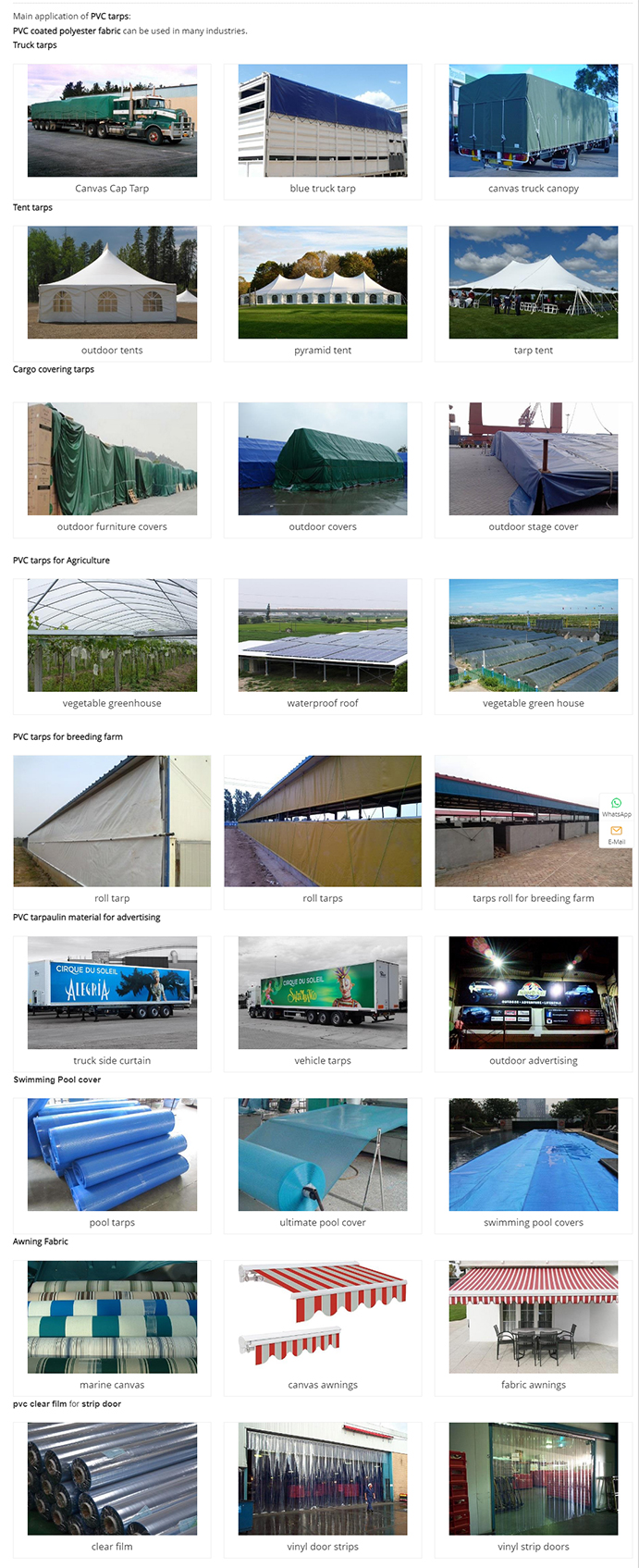

Custom tarpaulins are used across industries because they can be tailored to the job. Common applications include:

Company Name: Der (Shanghai DER New Material Co., Ltd)

Website: http://www.der-factory.com/en/

DER is an experienced manufacturer of PVC and PE tarpaulins, supplying customized cover solutions for global customers. With modern coating lines, lamination equipment, CNC cutting, and welding technology, DER supports both small prototype runs and high-volume, containerized production. The company emphasizes R&D, process control, and quick-turn sample services for OEM and ODM partners.

DER maintains an array of quality and compliance documentation to support international sales and project compliance. Typical certificates and test reports available on request:

We know buyers choose custom tarpaulin suppliers for dependability, accuracy and traceability. DER’s advantages include:

Custom tarps are only as good as their installation. Follow DER’s recommended best practices for reliable long-term use:

DER’s custom tarps are shipped worldwide. Representative markets include:

Clients range from logistics companies, builders and tent manufacturers to agricultural co-ops, event organizers and OEM equipment makers.

DER delivers custom tarps for many real-world projects — here are examples:

Target long-tail keywords that users commonly search for:

Lead times vary by order complexity. Typical turnaround for simple cut-and-hem tarps is 7–14 working days after artwork and sample approval. Heavily customized orders (full-colour printing, welded assemblies, special fittings) generally take 2–6 weeks. Rush services are available on request.

Yes — we offer Pantone color matching for base materials and full-colour digital or rotogravure printing for logos and graphics. We provide print proofs and small-run samples to confirm color and placement prior to mass production.

For large tarps, we typically recommend rope hems, welded corner plates, webbing straps sewn or welded into load-bearing seams, and distributed anchor points. These features spread loads evenly and reduce tear risk under wind or handling stress.

Yes — every custom order includes recommended installation guidelines and maintenance tips. For complex industrial installations we can provide CAD layouts, fitment drawings and on-site consultation for an additional project fee.

Begin by contacting our sales team via our contact page. Provide desired dimensions, material preference, expected usage, and artwork (if printing). We’ll prepare a quotation, sample options and recommended construction details. Samples and small test runs are available prior to full production.

DER New Material Co., Ltd

Website: http://www.der-factory.com/en/

Suggested URL for this page: http://www.der-factory.com/en/custom-tarps.html

© DER New Material — All rights reserved. For bespoke tarpaulin projects, prototypes or large-volume quotes please contact our export sales team via the website.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.

Message