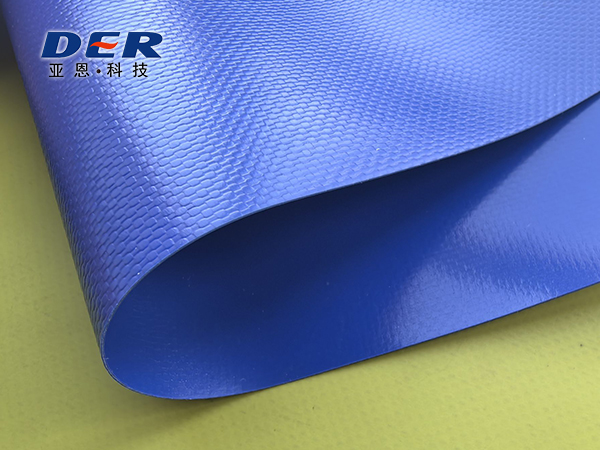

PVC Tarpaulin for Agriculture..

- 2025-12-17

Der factory is a leading global manufacturer of high-performance flame retardant fabrics, engineered for enhanced fire safety, durability, and industrial-grade performance. Our FR fabrics are widely used in tents, protective curtains, industrial partitions, warehouses, construction sites, and emergency shelters.

Our flame retardant textiles meet international safety standards including NFPA701, B1, M1, EN13501-1 while providing superior tensile strength, UV resistance, weatherproof performance, and long-term stability.

This page provides a comprehensive overview of our flame retardant fabrics, technical features, specifications, applications, manufacturing processes, quality certifications, global projects, and answers to frequently asked questions.

Flame retardant fabric is a specially engineered textile designed to resist ignition, slow down flame spread, and reduce smoke production when exposed to fire. Unlike conventional fabrics, FR fabrics incorporate advanced chemical additives or inherently flame-resistant fibers to meet strict industrial and commercial safety requirements.

At Der factory, we offer a wide range of flame retardant fabrics, including:

Each of our fabrics is carefully formulated for specific applications, combining advanced flame retardant chemistry with mechanical strength, flexibility, and durability. They are suitable for both indoor and outdoor environments where fire safety and visibility are critical.

Flame retardant fabrics achieve fire resistance through several mechanisms:

Der factory specializes in coating-based flame retardant solutions, providing highly reliable and durable fabrics suitable for industrial and commercial applications.

Common uses of our flame retardant fabrics include:

With Der factory flame retardant fabrics, clients can customize thickness, width, flame retardant grade, coating type, color, surface finish, and roll length to suit project-specific requirements. This level of customization ensures optimal performance across diverse industrial and commercial scenarios.

Our flame retardant fabrics are engineered to meet rigorous industry standards and offer excellent mechanical performance:

Der factory flame retardant fabrics are widely recognized by clients globally for their reliability, safety, and compliance with international fire safety standards.

Der factory flame retardant fabrics incorporate advanced technical features to ensure superior fire safety, durability, and long-term performance.

Der factory also provides extensive testing data, including tensile strength, tear strength, elongation, flame spread, smoke density, and chemical resistance, to ensure compliance with project specifications.

Der factory flame retardant fabrics are manufactured to meet a wide range of industrial and commercial requirements. The following table summarizes standard specifications, while custom sizes, thicknesses, colors, and coating types are available upon request.

| Item | Specification |

|---|---|

| Material | 100% Polyester / Nylon / Cotton canvas / Fiberglass base |

| Coating | PVC / PU / Silicone with flame-retardant additives |

| Thickness | 0.2 mm – 2.5 mm (customizable) |

| Width | 1.0 m – 3.0 m (standard), wider widths available on request |

| Flame Retardant Grade | NFPA701, B1, M1, EN13501-1 |

| Color | White, Grey, Blue, Red, Green, Transparent, Custom |

| Weight | 200 – 900 g/m² |

| Surface | Smooth / Matte / Embossed |

| Tensile Strength | Warp: 800 – 1000 N / 5 cm, Weft: 700 – 950 N / 5 cm |

| Tear Strength | Warp: 60 – 120 N, Weft: 55 – 110 N |

| Elongation at Break | Warp: 18% – 25%, Weft: 20% – 28% |

| Temperature Resistance | -20°C to +80°C |

| UV Resistance | Yes, optional UV-stabilized additives |

| Cold Resistance | -25°C / -40°C formulations available |

| Roll Length | 20 m, 30 m, 50 m or customized |

| Certifications | ISO 9001, SGS, NFPA701, EN13501-1, RoHS / REACH |

Custom requests for special coatings, anti-static treatment, waterproofing, or color matching are fully supported. Der factory works closely with clients to ensure each batch meets specific project requirements.

Der factory flame retardant fabrics are designed for a wide range of industrial, commercial, and emergency applications. Their versatility, durability, and fire resistance make them suitable for multiple environments:

Each application leverages the flame retardant fabric's superior fire resistance, mechanical strength, weatherability, and durability. Clients can specify customized coatings, colors, thicknesses, and sizes to meet exact project requirements.

Der factory’s flame retardant fabrics are exported worldwide, serving clients in North America, Europe, Asia, Australia, and Africa. They have been applied successfully in large-scale industrial projects, commercial venues, event management solutions, and emergency relief operations.

Der factory provides technical consultation for each project, ensuring the selected flame retardant fabric meets all local fire codes, safety standards, and functional requirements.

Der factory's flame retardant fabrics are produced using state-of-the-art manufacturing processes that ensure consistent quality, superior flame resistance, and long-term durability. Our production integrates advanced textile engineering, precision coating technology, and rigorous quality control measures.

High-quality base fabrics are selected depending on application requirements: polyester, nylon, cotton canvas, or fiberglass. Each base fabric undergoes pre-treatment to remove impurities, ensuring smooth coating adhesion and uniform flame retardant performance.

Base fabrics are coated or impregnated with PVC, PU, or silicone formulations containing flame retardant additives. The coating process is carefully controlled for uniform thickness and consistent fire-resistant properties. Multi-layer coatings are applied for enhanced mechanical strength and flame retardant longevity.

After coating, fabrics pass through controlled drying and curing tunnels. Precise temperature and humidity control ensure full polymerization of the coating, creating a stable and durable flame retardant layer. This process also prevents cracking, bubbling, or delamination during use.

The surface of the fabric is treated to achieve the desired finish: smooth, matte, embossed, or anti-slip. Additional treatments such as UV stabilization, anti-static coating, or waterproofing can be applied as required.

Every batch of flame retardant fabric undergoes stringent quality inspections, including:

Fabrics are cut into standard roll lengths or customized sizes according to customer requirements. Rolls are securely packaged with protective wrapping to prevent contamination, moisture ingress, or mechanical damage during transport.

Der factory continuously invests in modern production lines with automation, computer-controlled coating, and high-precision measurement systems to maintain consistency and high quality for all flame retardant fabrics.

Ensuring high-quality flame retardant fabric is fundamental to Der factory's philosophy. Our quality control system is designed to verify every aspect of the product before it reaches customers.

Der factory maintains complete traceability for every batch of fabric, providing clients with quality certificates, test reports, and compliance documentation.

Der factory flame retardant fabrics meet or exceed international safety standards. Our certifications include:

Certificates can be provided for every shipment upon request. Der factory maintains a rigorous quality documentation system, supporting large-scale industrial projects, OEM contracts, and international compliance requirements.

Our certificates validate that flame retardant fabrics manufactured by Der factory not only meet fire safety requirements but also demonstrate superior durability, environmental compliance, and mechanical performance.

Der factory offers full OEM and customization services for flame retardant fabrics. We work closely with clients to tailor fabric properties to project-specific requirements, ensuring optimal performance in every application.

Der factory supports both small-scale orders and large industrial projects, offering fast prototyping, technical consultation, and flexible production schedules to meet strict project timelines.

Der factory flame retardant fabrics are exported to over 80 countries, supporting industrial, commercial, and emergency applications. Below are representative case studies:

Proper installation ensures the flame retardant fabric performs as intended. Follow these guidelines:

Regular maintenance prolongs the lifespan of flame retardant fabrics:

It is a textile engineered to resist ignition, slow flame spread, and limit smoke production, providing safety for industrial, commercial, and emergency applications.

Yes. Der factory offers flexible customization for thickness (0.2–2.5mm or higher) and width (1.0–3.0m, or wider upon request).

Our fabrics meet NFPA701, B1, M1, EN13501-1, and can be adapted for specific local fire codes.

Yes. Optional UV-stabilized additives prevent yellowing and degradation for outdoor applications.

Yes. We provide OEM, custom color, logo printing, and specialized coatings according to client specifications.

Lead time varies based on quantity, specifications, and coatings. Typical production cycles range from 2–6 weeks.

Yes. All fabrics undergo rigorous mechanical, chemical, and flame-retardant testing, with certificates available for each batch.

Yes. With proper maintenance and handling, FR fabrics can be used for many years in industrial and commercial applications.

For inquiries, technical consultation, and custom orders, please contact us:

Our team is ready to assist with product selection, technical specifications, and project solutions for flame retardant fabrics worldwide.

© 2025 Der factory. All rights reserved.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.

Message