PVC Tarpaulin for Agriculture..

- 2025-12-17

I.Product introduction

Tarpaulin tool bags are usually made of a combination of multiple materials, among which tarpaulin material is its main component. The following is a detailed answer to the materials, production methods and advantages of tarpaulin tool bags:

Tarpaulin materials:

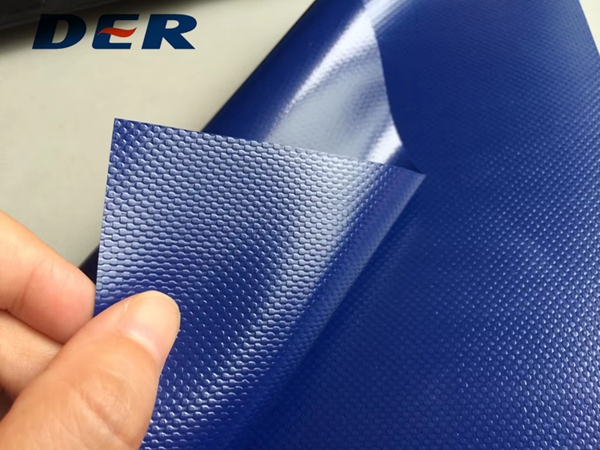

Tarpaulin is usually a thick cotton or linen fabric, named after its original use for sails. It is mostly made of plain or twill weave, and the warp and weft yarns are woven with multiple strands. Tarpaulins are divided into two categories: coarse canvas and fine canvas. Coarse canvas is commonly used in tool bags because it has better wear resistance, scratch resistance and waterproof performance.

The specifications of canvas fabrics are often expressed by "ann number". The larger the ann number, the heavier the fabric weight, the thicker the thickness, the coarser the surface texture, and the better the firmness and wear resistance. When making tarpaulin tool bags, fabrics with larger ann numbers are generally selected to ensure that the tool bags are strong and durable.

Other materials:

In addition to tarpaulins, tarpaulin tool bags may also use hard materials such as PVC and EVA as the lining to enhance the shape retention and durability of the tool bags. These materials have the characteristics of high thermal adhesion, super low temperature resistance, resistance to water, salt and other corrosive elements, and can well protect the tools from the external environment.

Production method

The production method of the tarpaulin tool bag may vary depending on the manufacturer and specific needs, but generally includes the following steps:

Cutting: Cut the tarpaulin into the required shape and size according to the design drawings.

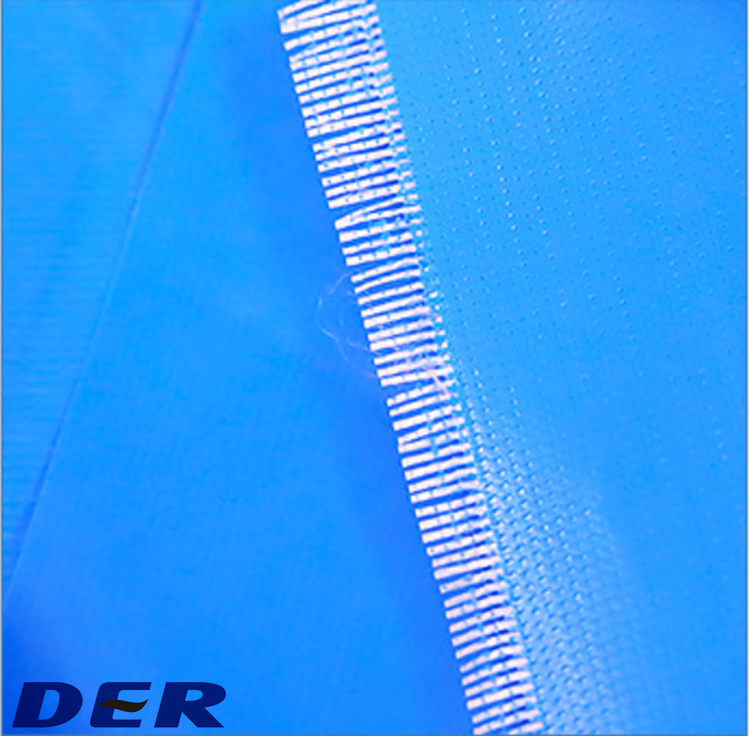

Sewing: Use a sewing machine or hand to sew the cut tarpaulin into the bag body, including the bottom, sides and top parts. During the sewing process, hard materials such as PVC and EVA may be added as lining to enhance the durability of the tool bag.

Reinforcement: Reinforcement treatment is carried out at key parts such as the bottom and side seams to improve the load-bearing capacity and durability of the tool bag.

Accessory installation: Install accessories such as zippers, buckles, shoulder straps, etc. for easy use and carrying.

Quality inspection: Conduct quality inspection on the completed tarpaulin tool bag to ensure that all performance indicators meet the standards.

II. Product specifications

1. Fabric specifications

|

Product name |

Tarpaulin tool bag |

|

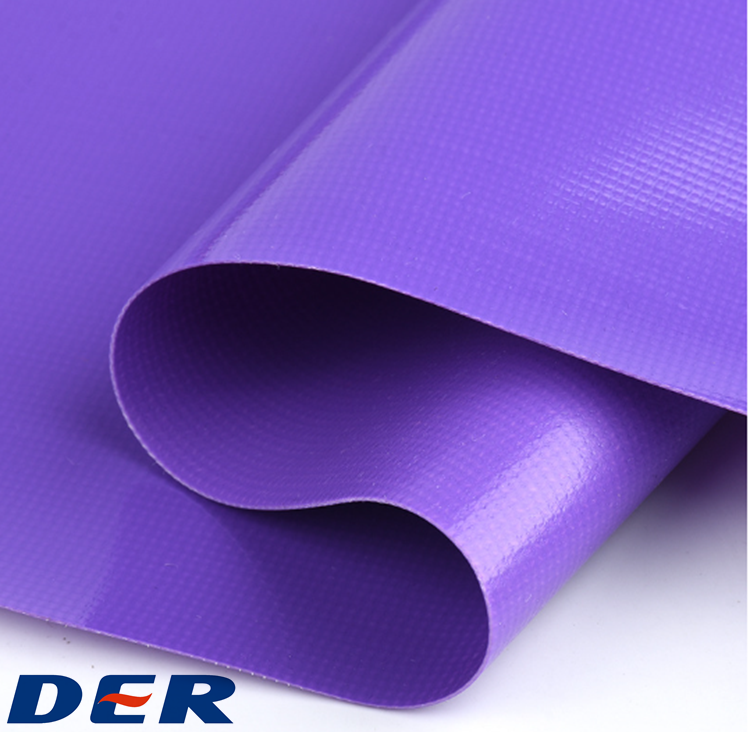

Product color |

custom |

|

Product material |

Durable PVC coated tarpaulin |

|

Yarn quantity |

1000D*1000D |

|

Product thickness |

0.6MM |

|

Product density |

20*20 |

|

Product weight |

650gsm |

|

Product Features |

Encrypted weaving, thickened and wear-resistant, flexible and easy to fold, tear-resistant ,stretch-resistant, waterproof |

|

Waterproof index |

99.99% |

|

Product usage |

Tarpaulin tool bag |

Strong and durable: The tarpaulin material itself has the characteristics of wear resistance, scratch resistance and waterproofness. With the reasonable production process and reinforcement treatment, the tarpaulin tool bag has high durability.

Good waterproof performance: The tarpaulin fabric treated with waterproof coating has excellent waterproof performance and can protect the tools from the influence of humid environments such as rain.

High cost performance: The price of tarpaulin fabric is relatively low and easy to obtain, which makes the tarpaulin tool bag have certain advantages in price. At the same time, its good durability also reduces the long-term use cost.

Large capacity: Tarpaulin tool bags are usually designed with larger sizes, which can accommodate more tools and equipment to meet the use needs in different scenarios.

Easy to clean and maintain: Tarpaulin material is relatively easy to clean and maintain, and it can be restored to a neat state with a simple wipe or wash.

In summary, the tarpaulin tool bag is widely welcomed for its strong and durable, good waterproof performance and high cost performance. Paying attention to details and reinforcement during the production process can further improve its durability and practicality.

III.Product applications

IV.Product profile

Anhui Yaen New Materials Co., Ltd. is one of the leading heavy-duty PVC coated tarpaulin manufacturers in China with more than 20 years of experience. We have been committed to the research, development and manufacture of tarpaulin products since 1997. We have a large number of advanced equipment, scientific management, first-class technology, continuous design and professional team to meet market needs in a timely manner. As a professional PVC tarpaulin manufacturer with more than 20 years of production and sales experience. We have 2 knife coating production lines, 4 calenders, 8 laminating machines, producing double-layer and coated PVC tarpaulin materials for various fields. We are a high-tech industrial company certified by Zhejiang and Anhui provinces, and have won the National Technology Progress Award. Now, we have 8 doctors, 23 postgraduates and many employees with bachelor's degrees to improve and develop new products and production processes, which ensures DER as a developing coated fabric company.

Elaine Zhang销售经理

Tel:+86 199 5504 7834(微信)

E-mail: elaine@der-factory.com

Web: www.der-factory.com/en

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.

Message