PVC Tent Fabric – Heavy Duty Waterproof ..

- 2025-10-28

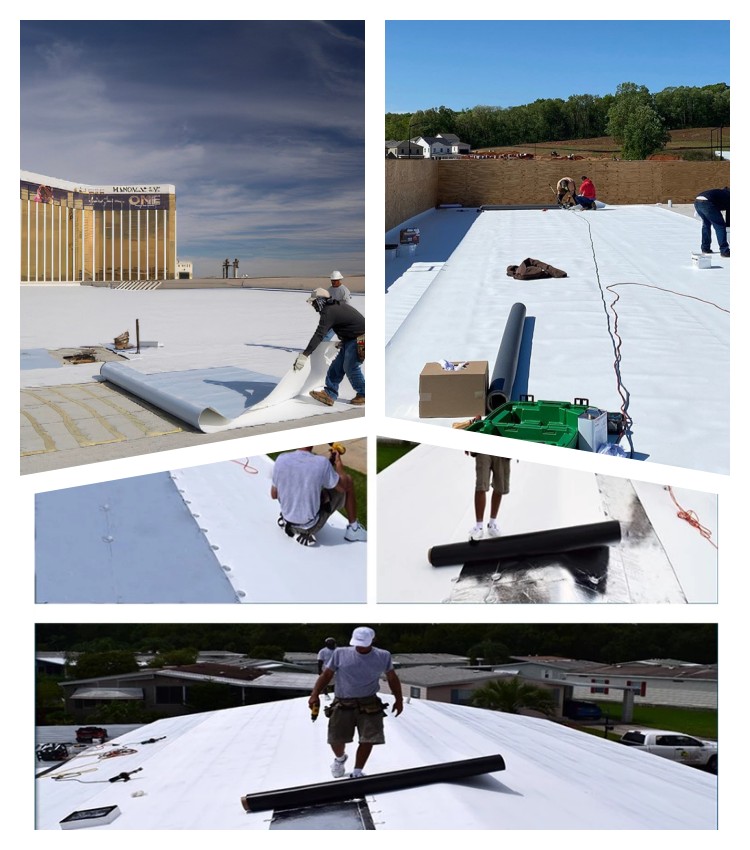

Membrane Waterproofing Roof Materials

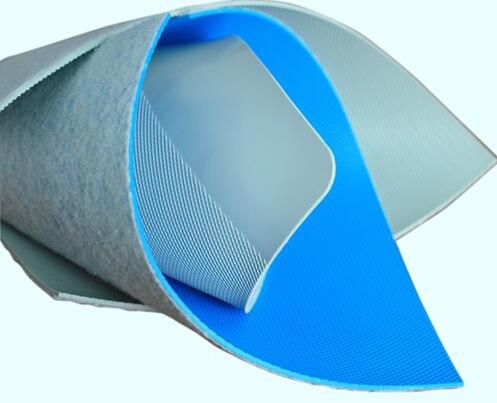

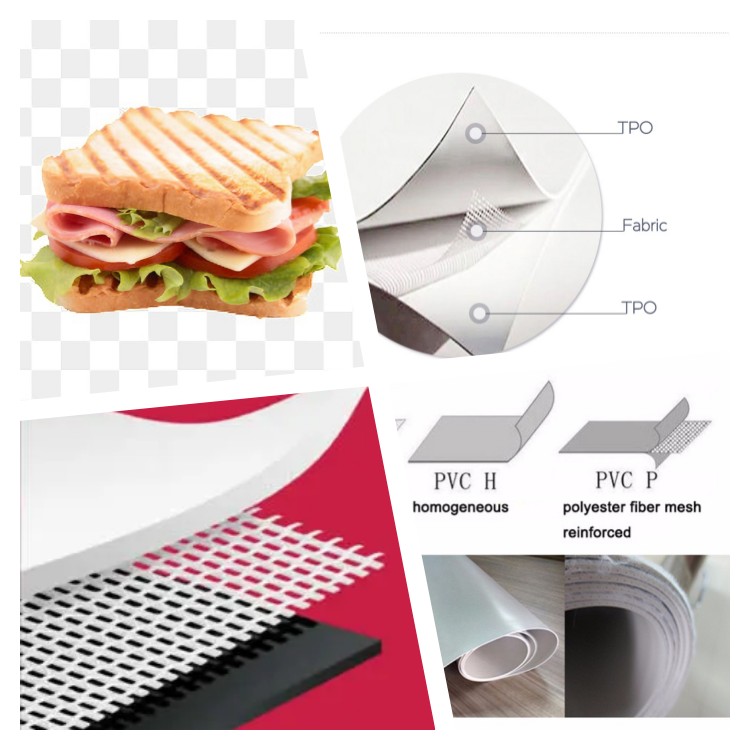

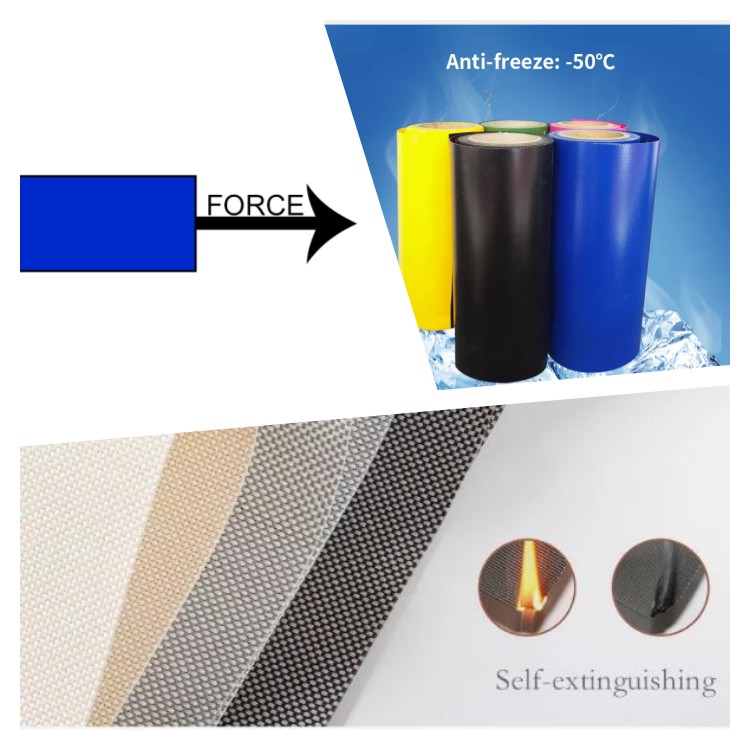

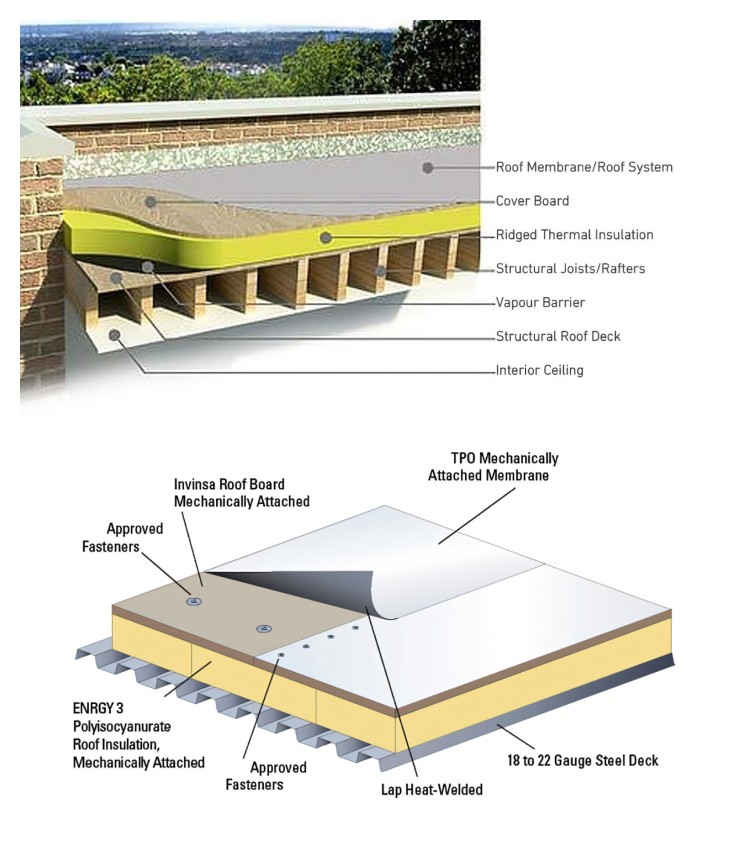

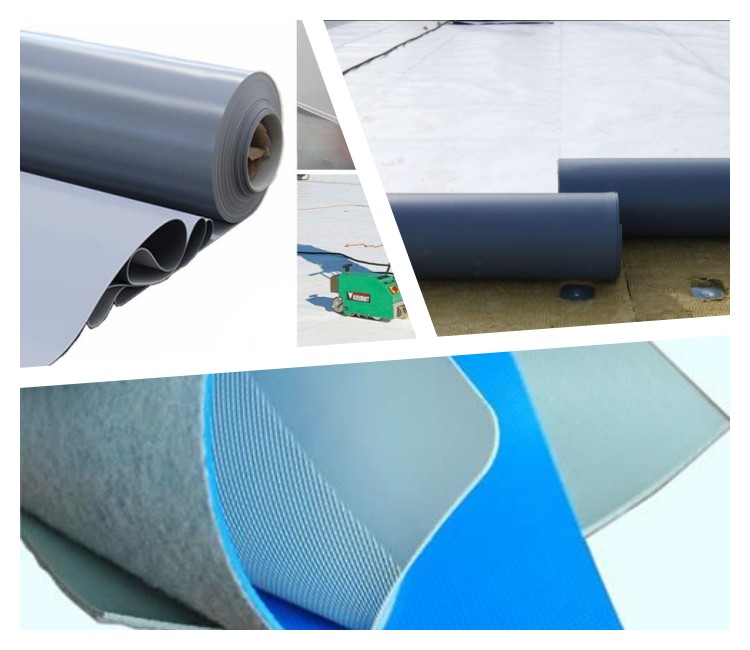

Waterproofing is a protective measure that makes a surface water-resistant and prevents liquids from penetrating undesirable surfaces. Waterproof membrane for construction is one of the most preferred waterproofing materials in the construction industry which is very preferred in roof insulation applications with its ease of use, and price/performance advantage. We are selling two type of the membranes, one is PVC (Polyvinyl Chloride) – this membrane consists of two PVC plies that sandwich a polyester reinforcement sheet. The other is TPO (Thermoplastic Polyolefin) – to produce the TPO membrane, manufacturers will polymerize polypropylene and ethylene-propylene rubber, like PVC, two TPO plies sandwich a polyester reinforcement sheet.When the 90s came, TPO entered the mainstream roofing industry and started to become a popular option, one of the reasons is that it doesn’t contact chlorine as well as plasticizers and halogens which are all harmful to the environment. It is also a good alternative to PVC as they have similar benefits.

|

Comparison Metric |

PVC |

TPO |

Result |

|

Years in Production as Roofing Material |

60+ years with several reformulations |

30+ years with multiple reformulations |

No Advantage |

|

Membrane Thickness |

From .036 to .090 |

From .045 to .080 |

No Advantage |

|

Seaming Method |

Heat Welded |

Heat Welded |

No Advantage |

|

Chemical Resistance |

Excellent (nonreactive to most chemicals) |

Good (may react to oil or grease exhaust) |

PVC |

|

Fire Resistance |

Excellent |

Poor |

PVC |

|

Tear Strength (pound force p/ in) |

45 lbf |

55 lbf |

TPO |

|

Break Strength (pound force p/ in) |

200 lbf |

220 lbf |

TPO |

|

Average Cost Installed |

Can range from $5 to $12 per square foot depending on membrane thickness |

Can range from $7 to $13 per square foot depending on membrane thickness |

PVC |

|

Color |

To achieve an energy efficient cool roof, `both can go for the color white which effectively reflects the sun’s energy. This also reduces the building’s energy consumption as well as the urban heat island (UHI) effect. |

||

Waterproofing TPO Roof Membrane Application Study

Both TPO and PVC roofing will be applied in most commercial buildings well. However, a few factors have to be kept in mind:

TPO Roof Membrane Product Specification

|

Item |

Specification |

|||||

|

H |

L |

P |

G |

GL |

||

|

The resin thickness of Middle fabric, mm≥ |

— |

0.40 |

||||

|

Maximum tension,N/cm ≥ |

— |

200 |

250 |

— |

200 |

|

|

Tension strength,Mpa≥ |

12 |

|

|

12 |

|

|

|

Maximum tension elongation,%≥ |

|

|

15 |

|

|

|

|

Fracture elongation,%≥ |

500 |

250 |

|

400 |

200 |

|

|

Heat treatment size change rate %≤ |

2.0 |

1.0 |

0.5 |

0.1 |

0.1 |

|

|

Low temperature bend |

-40°C No crack |

|||||

|

Water tightness |

0.3Mpa,2h, No seepage |

|||||

|

Attack resistance |

0.5kg·m,No seepage |

|||||

|

Static charge resistance |

— |

20kg ,No seepage |

||||

|

Seam strip strength ,N/mm≥ |

4.0 or Membranes break |

3.0 |

||||

|

Right-angle tear strength,N/mm≥ |

60 |

|

|

60 |

|

|

|

Trapezoid tear strength N≥ |

— |

300 |

450 |

|

350 |

|

|

Bibulous rate (70°C 168h), % |

After soaking≤ |

4.0 |

||||

|

Air-cure later≥ |

-0.40 |

|||||

|

Heat aging (115°C) |

Time |

672h |

||||

|

Appearance |

No blister,flaw,delamination,coherence,hole |

|||||

|

Tensile strength retention,%≥ |

90 |

|||||

|

Elongation rate of keeping,%≥ |

90 |

|||||

|

Low temperature bend |

-40°C, No crack |

|||||

|

Chemistry resistance |

Appearance |

No blister,flaw,delamination,coherence,hole |

||||

|

Tensile strength retention,%≥ |

90 |

|||||

|

Elongation rate of keeping,%≥ |

90 |

|||||

|

Low-temperature bending |

-40°C, No crack |

|||||

|

Artificial weather accelerated aging |

Time |

1500hb |

||||

|

Appearance |

No blister,flaw,delamination,coherence,hole |

|||||

|

Tensile strength retention%≥ |

90 |

|||||

|

Elongation rate of keeping%≥ |

90 |

|||||

|

Low temperature bend |

-40°C ,No crack |

|||||

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.

Contact Us