PVC Tarpaulin for Agriculture..

- 2025-12-17

Chemical liquid bag tarpaulin is a tarpaulin material specially designed for the packaging and transportation of chemical liquids. Has the following material properties:

High strength: chemical liquid bag tarpaulin usually has high strength and can resist external pressure and impact.

Good elasticity: Excellent elasticity ensures the adaptability and stability of the tarpaulin in the packaging and transportation process.

Tensile, tear and peel resistance: These characteristics make the tarpaulin difficult to break or tear during transportation.

Fire retardant: For some flammable chemicals, fire retardant characteristics are particularly important.

Anti-ultraviolet, anti-bacterial and anti-mildew: During long-term storage and transportation, tarpaulin needs to be able to resist ultraviolet radiation and microbial erosion.

Waterproof and anti-fouling: chemical liquids usually have a certain corrosive or polluting nature, so the tarpaulin needs to have the ability to waterproof and anti-fouling.

High temperature and cold resistance: the transportation of chemicals may involve various climatic conditions, so tarpaulin needs to be able to adapt to different temperature environments.

Uses: chemical liquid bag tarpaulin is mainly used for filling and transporting various chemicals, such as plasticizers, synthetic resins, cleaners, disinfectants and so on. It can also be used for the packaging and transportation of other fluid substances, such as food, beverages, etc.

Specifications and processing: Chemical liquid bag tarpaulin can be produced in a variety of specifications to adapt to different capacity and size of liquid bags.

The processing process usually adopts high temperature heat sealing to ensure the tightness and air tightness of the tarpaulin and prevent liquid leakage.

The choice of tarpaulin should be determined according to the specific chemical properties and the use environment. Before use, the tarpaulin should be checked for integrity and tightness to ensure that it can meet the requirements of packaging and transportation.

In summary, the chemical liquid bag tarpaulin is a kind of material with high strength, high elasticity, fire retardant, anti-ultraviolet, waterproof and anti-fouling and other properties, which is specially used for the packaging and transportation of chemical liquids.

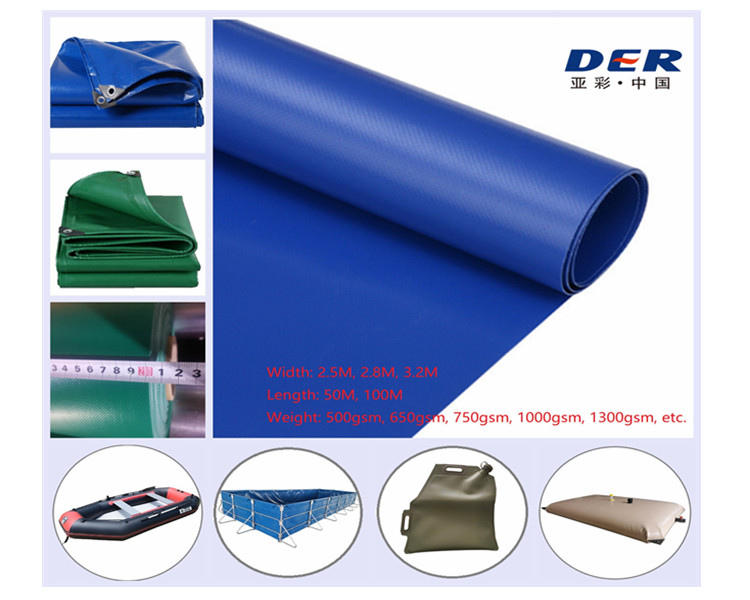

2、Specification parameters:

|

product |

Chemical liquid bag tarpaulin |

|

material |

PVC coated |

|

gsm |

850g、950g、1050g、1200g |

|

thickness |

customizable |

|

colour |

customizable |

|

sizes |

customizable |

|

features |

Waterproof and mildew resistant, aging resistant, wear resistant, UV resistant, four seasons universal. |

|

Application |

Fill and transport all kinds of chemicals, biogas bags, water bags, oil naan, bridge pre-pressure water bags, fish ponds, etc |

2.1 Technical Specifications

|

item |

value |

unit |

test method |

|

Basic fabric |

1000D*1000D |

Denier |

|

|

construction |

30*30 |

Threads/Inch2 |

|

|

total weight |

950 |

gsm |

|

|

Breaking strength |

L:4500 |

DIN53354 |

|

|

W:4000 |

|||

|

Tearing strength |

L:500 |

N/5CM |

DIN53356 |

|

|

W:450 |

||

|

Adhesion |

120 |

N/5CM |

DIN53357 |

|

FR |

B1/B2/M1/M2/NFPA701 (According to customer request) |

||

|

Applicable |

-30—70 |

°C |

|

2.2 Accessories: Chemical liquid bag tarpaulin usually involves multiple accessories to ensure its integrity, functionality and safety.

Liquid bag cloth: the main material used to form the main part of the liquid bag. May use PVC mesh cloth, TPU mesh cloth and other environmental protection cloth, with high strength, anti-mildew, no yellow, flame retardant, light and other characteristics.

Sealing belt: Used to seal the mouth of the liquid bag to prevent liquid leakage. Depending on the size and use of the liquid bag, the design and material of the sealing tape may vary.

Asbestos rope: May be used to enhance the tightness of liquid bags or as reinforcement material. The specific use and location may vary depending on the bag design and use.

Gas cover: In some cases, it may be necessary to use gas cover to enhance the air tightness of the liquid bag and ensure that the liquid does not leak due to external pressure.

Other accessories: Depending on the specific purpose and design of the liquid bag, other accessories may be required, such as handles, drawstrings, reinforcement pieces, etc., to enhance the practicality, portability, or safety of the liquid bag.

3. Finished product display:

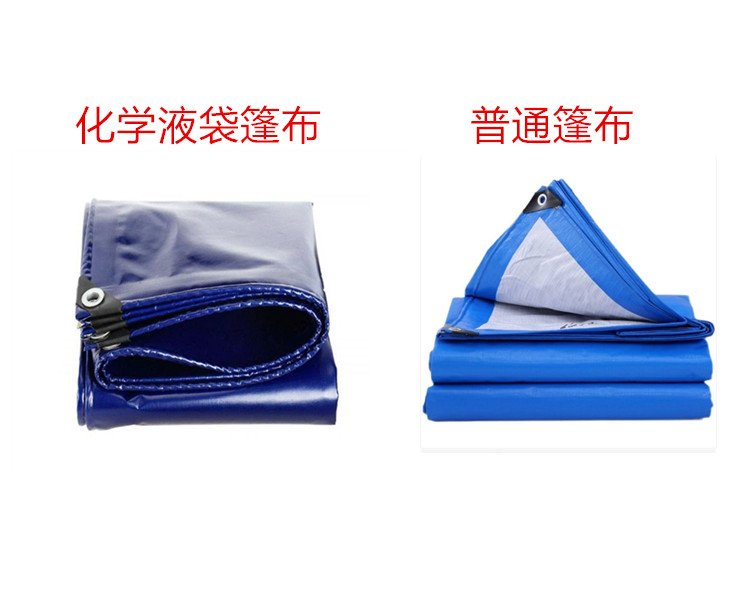

4. Comparison of finished products:

Comparison of advantages and disadvantages of chemical liquid bag tarpaulin and ordinary tarpaulin:

There are significant differences between chemical liquid bag tarpaulin and ordinary tarpaulin, and these differences are mainly reflected in the following aspects:

Material characteristics:

Chemical liquid bag tarpaulin: usually made of special materials, such as polyethylene (PE) or polyvinyl chloride (PVC) coated plastic cloth, these materials have waterproof, anti-corrosion, high temperature resistance, low temperature resistance, UV resistance, flame retardant and other characteristics. These characteristics make it resistant to chemical corrosion and pollution, and ensure the safe transportation of chemical liquids.

Ordinary tarpaulin: generally made of cotton, polyester fiber, nylon and other ordinary materials, with waterproof, breathable, tear resistance and other general properties. However, compared with the chemical liquid bag tarpaulin, its corrosion resistance and high temperature resistance are weak.

Purpose:

Chemical liquid bag tarpaulin: mainly used for the packaging and transportation of chemical liquids, such as plasticizers, synthetic resins, cleaners, disinfectants and so on. Its special materials can ensure the safe storage and transportation of chemical liquids, preventing liquid leakage and pollution of the environment.

Ordinary tarpaulin: widely used, such as building protective cover, truck cover, camping tent, stage background cloth and so on. Although it can also be used for some simple liquid or cargo covering, it is not suitable for the packaging and transportation of chemical liquids.

Specifications and processing:

Chemical liquid bag tarpaulin: various specifications can be customized according to different chemical liquids and liquid bag sizes. In the processing process, high temperature heat sealing and other technologies are usually used to ensure the tightness and air tightness of the tarpaulin and prevent liquid leakage.

Ordinary tarpaulin: the specifications are more uniform, but it can also be customized according to specific needs. The processing process is relatively simple, mainly to ensure the flatness and beauty of the tarpaulin.

Safety and environmental protection:

Chemical liquid bag tarpaulin: due to its special materials and processes, it has high safety and environmental protection. It can prevent chemical liquid leakage and reduce environmental pollution. At the same time, some chemical liquid bag tarpaulin also has flame retardant performance, improving safety.

Ordinary tarpaulin: relatively weak in terms of safety and environmental protection. Although it can also play a certain protective role, it has limited protective capacity for dangerous goods such as chemical liquids.

In summary, there are significant differences between chemical liquid bag tarpaulin and ordinary tarpaulin in material characteristics, uses, specifications and processing, safety and environmental protection. Chemical liquid bag tarpaulin is specially used for the packaging and transportation of chemical liquids, with higher safety and environmental protection; The ordinary tarpaulin is widely used in various occasions, but is not suitable for the packaging and transportation of chemical liquids.

5、Product Application

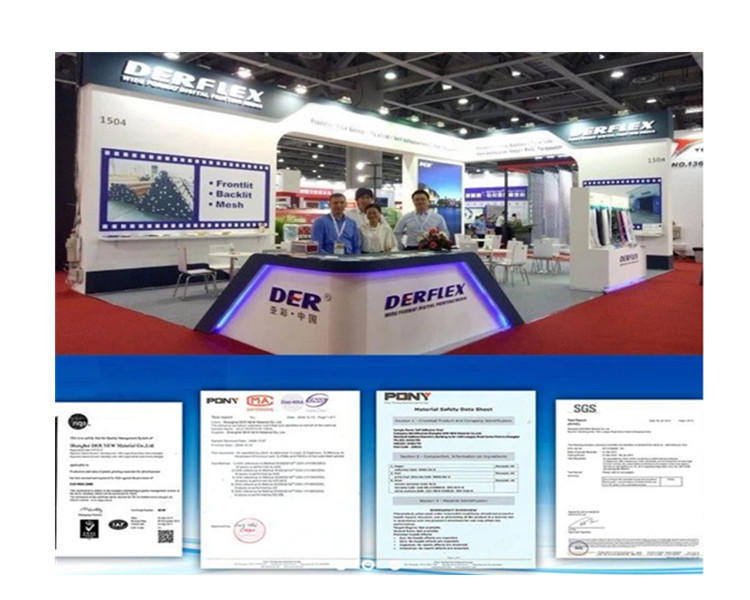

6、 Company Profile

Anhui Yanen New Material Technology Co., Ltd. is located in Zhangbaling plastic polymer Industrial Park, Zhangbaling Town, Mingguang City, Chuzhou City, Anhui Province, is a professional manufacturer of PVC flag, PVC tarpaulin, PVC coil, TPU coated cloth, sunscreen cloth, super transparent PVC film, swimming pool lining. Our factory accepts customized service of finished product processing, OEM can produce functional products of different thickness and softness; A wide range of products and competitive prices, selling well in more than 100 countries around the world.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.

Message