PVC Tarpaulin for Agriculture..

- 2025-12-17

1. Production process:

Main raw materials

PVC resin: As the main component of swimming pool film, PVC resin (polyvinyl chloride) is a vinyl polymer with non-toxic and environmentally friendly characteristics.

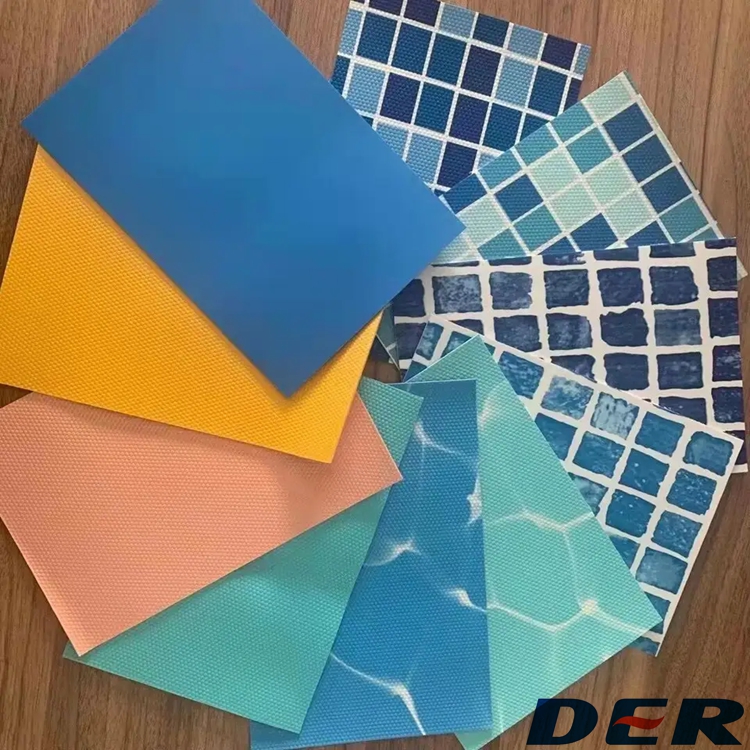

Additives: During the production process, fillers, plasticizers, stabilizers, colorants and other auxiliary materials are also added to enhance the performance and aesthetics of the swimming pool film.

Production steps

Raw material preparation: PVC resin is mixed with various additives in a certain proportion to ensure the quality and performance of the swimming pool film.

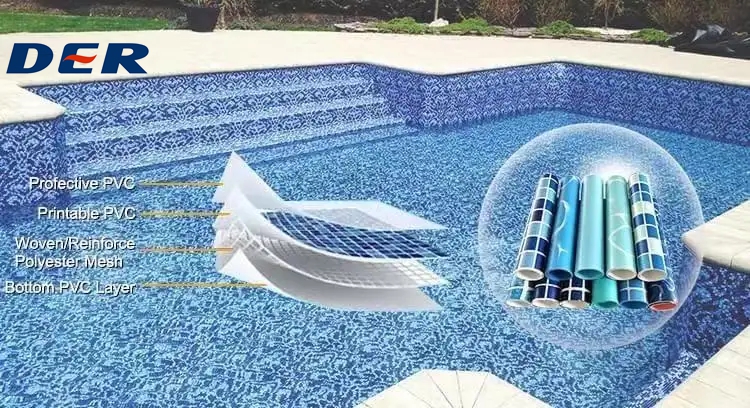

Calendering or extrusion: The mixed raw materials are processed by a calender or extruder to form a continuous sheet substrate. This step is the key to the formation of swimming pool film. By controlling parameters such as temperature and pressure, swimming pool films of different thicknesses and widths can be obtained.

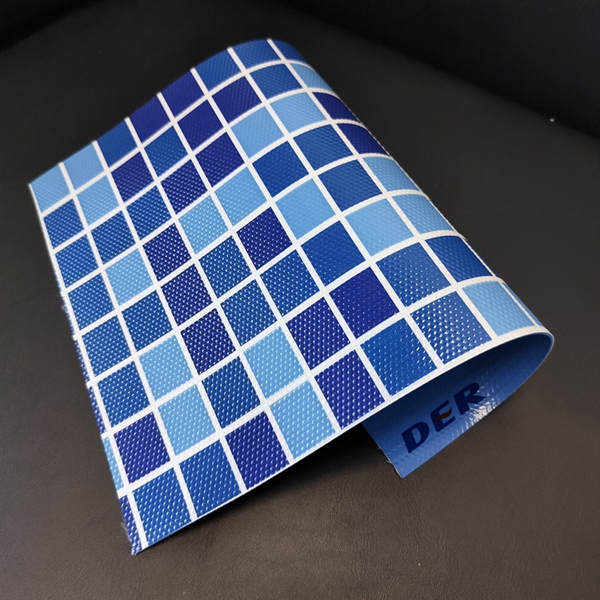

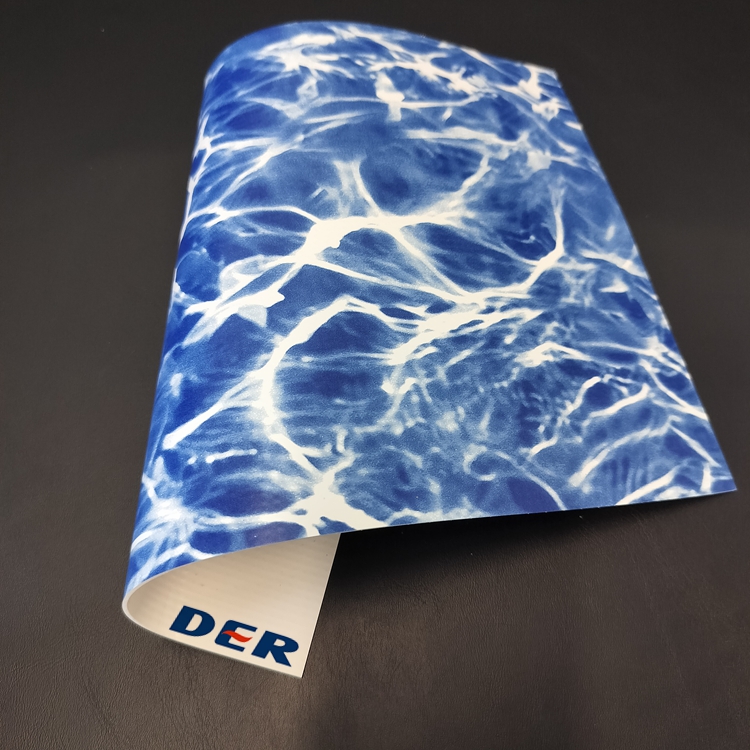

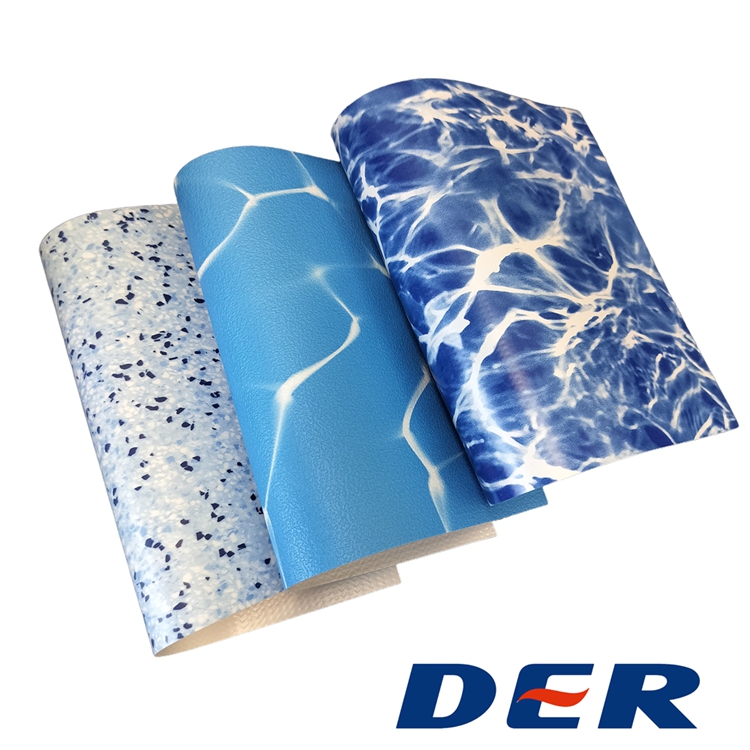

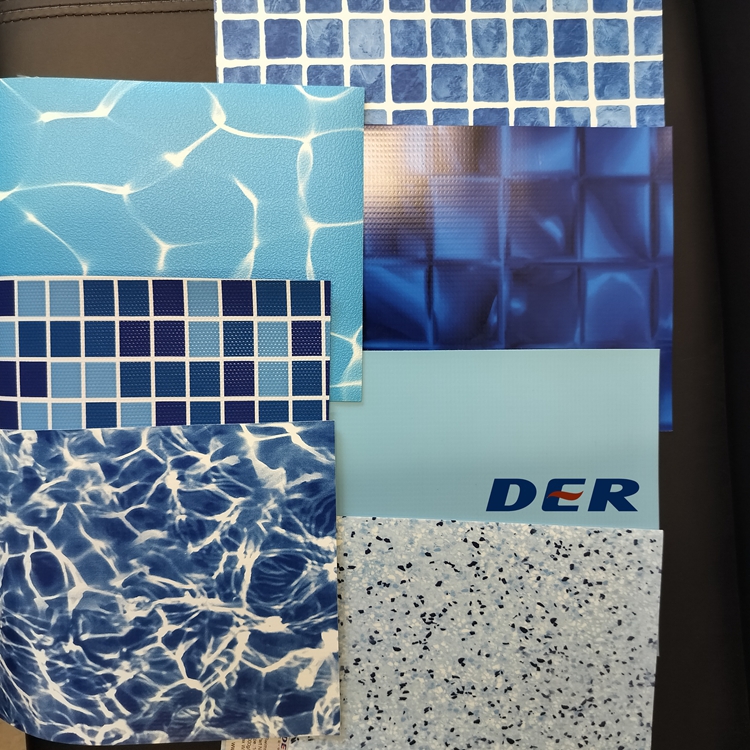

Surface treatment: The surface of the swimming pool film is treated to improve its waterproof, anti-slip and wear-resistant properties. This may include steps such as coating a protective layer and printing decorative patterns.

Quality inspection: During the production process, the swimming pool film needs to be quality inspected to ensure that it meets relevant standards and requirements. This may include steps such as thickness inspection, width inspection, and tensile testing.

Cutting and packaging: According to customer needs, the pool film is cut into suitable sizes, packaged and marked for transportation and installation.

Features

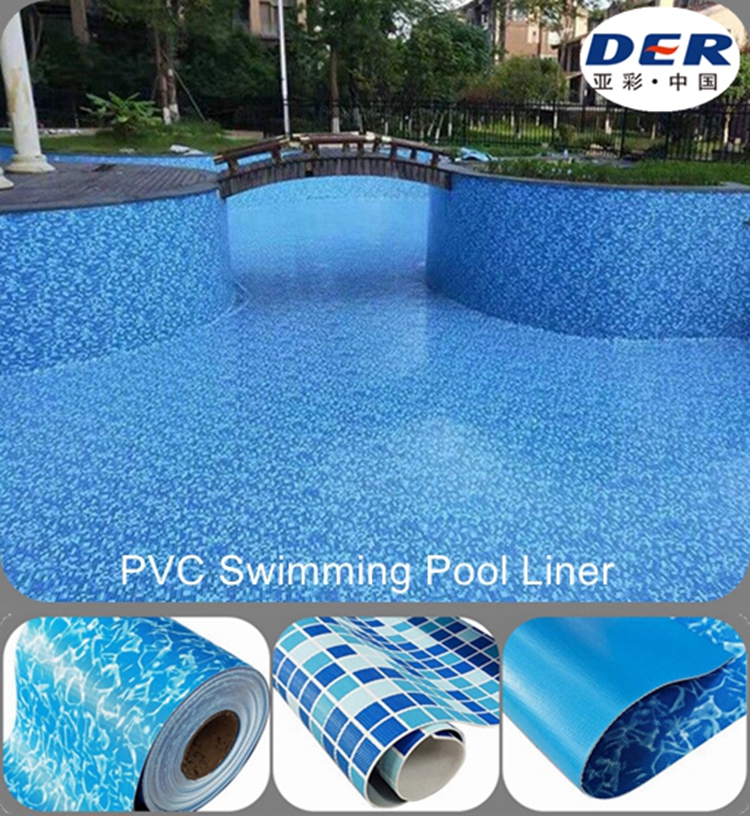

Waterproof performance: The pool film has excellent waterproof performance, which can effectively prevent water penetration and leakage, and ensure the safe use of the swimming pool.

Wear resistance: The surface of the film has been specially treated and has extremely high wear resistance. It can withstand the impact of human traffic and water flow in the swimming pool and maintain good condition for a long time.

Anti-slip performance: The swimming pool film has good anti-slip performance and can provide sufficient friction in a humid environment to reduce the risk of falling or slipping.

Anti-fouling performance: The surface of the film is smooth and not easy to adhere to dirt. It is easy to clean and maintain, which helps to keep the swimming pool clean and hygienic.

Corrosion resistance and anti-aging: The swimming pool film is made of corrosion-resistant and anti-aging materials, which can resist the corrosion of chlorine and other chemicals and extend the service life.

2.regular weight

|

Items |

Subscription |

Specification |

Width(M) |

|

DG1199-YC

|

swimming pool liner tarpaulin

|

1000D*1000D 9*9 2000gsm |

Max 3.2

|

III. Company Profile

Anhui DER New Materials Co., Ltd. is one of the leading heavy-duty PVC coated tarpaulin manufacturers in China with more than 20 years of experience. We have been committed to the research, development and manufacture of tarpaulin products since 1997. We have a large number of advanced equipment, scientific management, first-class technology, continuous design and professional team to meet market needs in a timely manner. As a professional PVC tarpaulin manufacturer with more than 20 years of production and sales experience. We have 2 knife coating production lines, 4 calenders, 8 laminating machines, producing double-layer and coated PVC tarpaulin materials for various fields. We are a high-tech industrial company certified by Zhejiang and Anhui provinces, and have won the National Technology Progress Award. Now, we have 8 doctors, 23 postgraduates and many employees with bachelor's degrees to improve and develop new products and production processes, which ensures DER as a developing coated fabric company.

Anhui DER New Material Technology Co., Ltd

For more information,pls contact ElaineZhang

TEL:(+86)199 5504 7834(Wechat/(Whatsapp)

E-mail:Elaine@der-factory.com

Web: www.der-factory.com/en

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.