PVC Tarpaulin for Agriculture..

- 2025-12-17

1. Chemical structure and properties of DOP, DOIP, and DINP

DOP: is a classic plasticizer containing phthalic acid and 2-ethylhexanol in its chemical structure. It has good flexibility and plasticity, but is negatively affected by environmental and ecological factors.

DOIP: It is a plasticizer generated by the reaction of phthalic acid and isooctyl alcohol. Compared with DOP, DOIP has superior environmental performance and has less impact on the environment.

DINP: Similar to DOIP, it is also a product of phthalic acid and isooctyl alcohol, but has a larger relative molecular weight and can provide better softness and cold resistance.

2. Impact on tarpaulin production

Softness and plasticity: Due to its small molecular weight, DOP makes the tarpaulin excellent in softness and plasticity, but it has certain problems in terms of environmental protection. While DOIP and DINP provide similar softness and plasticity, they have more environmental advantages and are suitable for production environments with high environmental requirements.

Weather resistance and cold resistance: Due to its relatively large molecular weight, DINP shows better weather resistance and cold resistance, allowing the tarpaulin to maintain stable performance and extend its service life under severe weather conditions. Compared with DOP, DOIP has improved weather resistance and cold resistance, but it is still not as good as DINP.

Environmental performance: In today's context of increasing environmental awareness, DOIP and DINP are favored for their relatively high environmental performance. Especially because of its large molecular weight and low volatility, DINP has great application potential in fields with high environmental protection requirements.

3. Advice on selecting appropriate plasticizers

In tarpaulin production, selecting appropriate plasticizers requires comprehensive consideration of factors such as product performance, environmental protection requirements, and cost. When environmental protection requirements are strict, it is recommended to use DOIP or DINP to reduce the negative impact on the environment. In some special cases, DOP may still be an economical option, but its environmental performance needs to be carefully considered when choosing.

4. Cost and sustainability considerations

In addition to product performance and environmental requirements, cost is another important consideration in tarpaulin production. DOP is usually a more affordable option, but with the strengthening of environmental regulations and the increase in market demand for environmentally friendly products, the prices of DOIP and DINP have been relatively stable, and the cost gap has gradually narrowed. In the long term, choosing more environmentally friendly plasticizers may help improve product sustainability and meet market demand for environmentally friendly products.

5. Technology application and R&D innovation

With the continuous advancement of science and technology, technological innovation is also continuing in the field of tarpaulin production. It is possible to achieve higher performance and lower environmental impact by improving production processes or introducing new plasticizers. Manufacturers can work with chemical engineers and materials scientists to find innovative plasticizers to meet changing market needs.

6. Regulatory Compliance

When selecting plasticizers, manufacturers also need to consider relevant regulations and standards. Different countries and regions may have different regulatory requirements and may have restrictions on the use of certain plasticizers. Therefore, when selecting plasticizers, you must ensure that the product complies with local and international regulatory standards to avoid possible legal issues and market risks.

7. Market Trends and Consumer Preferences

As consumers continue to pay more attention to environmentally friendly products, market trends are also moving towards more environmentally friendly and sustainable products. Therefore, manufacturers need to keenly capture market trends and consumer preferences when selecting plasticizers to ensure that products can meet market demand and remain competitive in a highly competitive market.

Choosing appropriate plasticizers in tarpaulin production is not only related to product performance and quality, but also involves the sustainable development and market competitiveness of the enterprise. Therefore, manufacturers should comprehensively consider various factors, weigh the pros and cons, and make informed decisions to produce tarpaulin products that are both high-performance and environmentally friendly.

Application: As a multifunctional covering material, tarpaulin is widely used in agriculture, industry, construction and outdoor fields. In the production process of tarpaulin, plasticizers play a vital role, among which DOP, DOIP, and DINP are common plasticizers.

1. Agricultural covering tarpaulin:

Agricultural tarpaulin is a key material used to protect crops. Due to its excellent softness and plasticity, DOP is often used in the production of agricultural covering tarpaulins to ensure that it can fit the contours of the ground when covering plants, effectively protecting plants from the natural environment.

2. Truck tarpaulin:

Truck tarps are used to cover transported goods and protect them from rain, wind, snow and other natural conditions. In the production of truck tarpaulins, DOP is often used, which makes the tarpaulins have excellent flexibility, can easily cover goods, and maintain stability during long-distance transportation.

3. Canvas tent:

As an outdoor shade and temporary structure, canvas tents need to maintain stable performance in the outdoor environment. In the production of canvas tents, DINP is more commonly used because of its relatively large molecular weight, which can provide excellent weather resistance and cold resistance and adapt to various climate conditions.

4. Outdoor open storage coverage:

Outdoor open storage coverings need to maintain stable performance under harsh weather conditions and resist the erosion of wind, rain and ultraviolet rays. In this scenario, the weather resistance advantages of DINP are fully utilized to ensure that the tarpaulin maintains excellent performance in the outdoor environment for a long time.

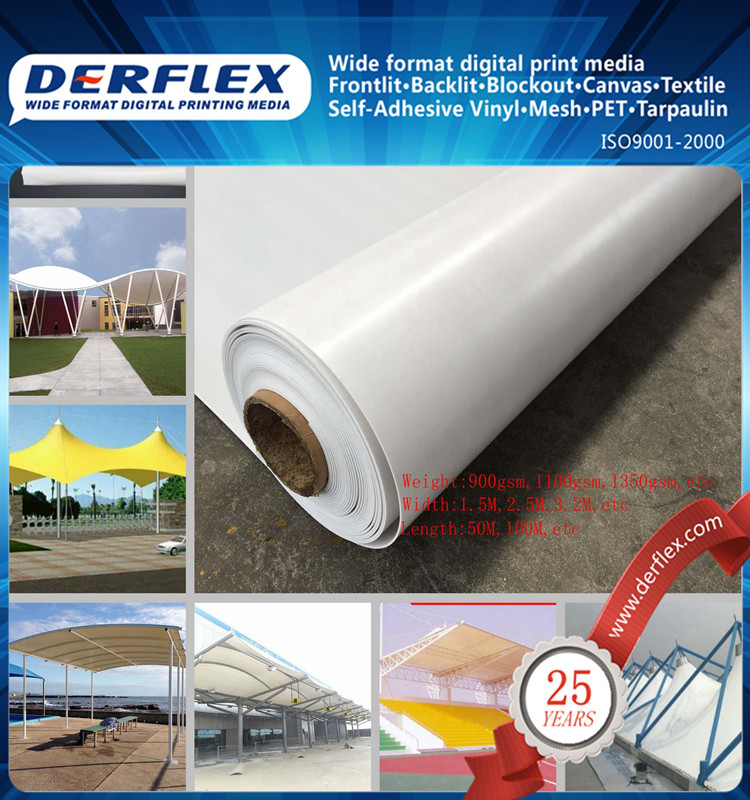

5. Stadium tarpaulin structure:

Sports stadium tarpaulin structures need to provide reliable shade and protection under a wide range of weather conditions. Due to its relatively good environmental performance and good plasticity, DOIP is often used in the production of stadium tarpaulins to meet the dual needs of environmental protection and performance.

in conclusion:

Plasticizers DOP, DOIP, and DINP play an indispensable role in tarpaulin production, and their selection is directly related to the performance, applicable scenarios, and environmental protection of the tarpaulin. Different application scenarios have different requirements for plasticizers. Manufacturers need to choose the most appropriate plasticizer according to specific needs to ensure that the tarpaulin can perform best in various environments while complying with environmental regulations and market demand. . With the continuous innovation of technology and the increasing emphasis on environmental protection, the field of tarpaulin production will also usher in the application of more new plasticizers, pushing the entire industry to develop in a more sustainable direction.

Anhui DER New Material Technology Co., Ltd. is located in Zhangbaling Plastic Polymer Industrial Park, Zhangbaling Town, Mingguang City, Chuzhou City, Anhui Province, whici is a professional manufacturer for PVC tarpaulin, PVC membrane, TPU coated fabrci, sun screen fabrics, super clear PVC film, swimming pool liner. Knife coating, hot-melting productions for OEM production on different thickness and softness functional products.; Virous product catagories and competitive price, which is popular sold more than 100 countries all over the world.

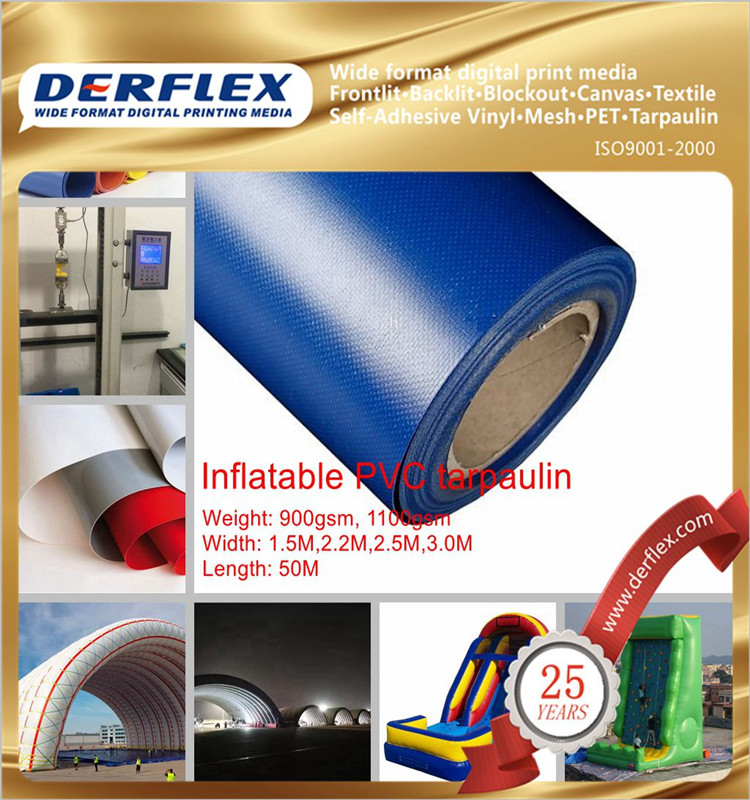

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.