PVC Tarpaulin for Agriculture..

- 2025-12-17

Regular cleaning, avoiding exposure to ultraviolet light, preventing contact with chemicals, regular inspection and maintenance, proper storage and handling, and using specialized protective coatings are effective methods to extend the service life of the surface adhesive layer of tarpaulin. Choosing suitable protective coatings can be based on the tarpaulin's requirements and usage environment. For instance, if the tarpaulin needs to be used in a rainy environment, polyurethane or PVC coatings might be more suitable, whereas situations requiring high-temperature resistance might benefit from silicone lacquered. Therefore, selecting the appropriate protective coating can better protect the tarpaulin surface and prolong its service life.

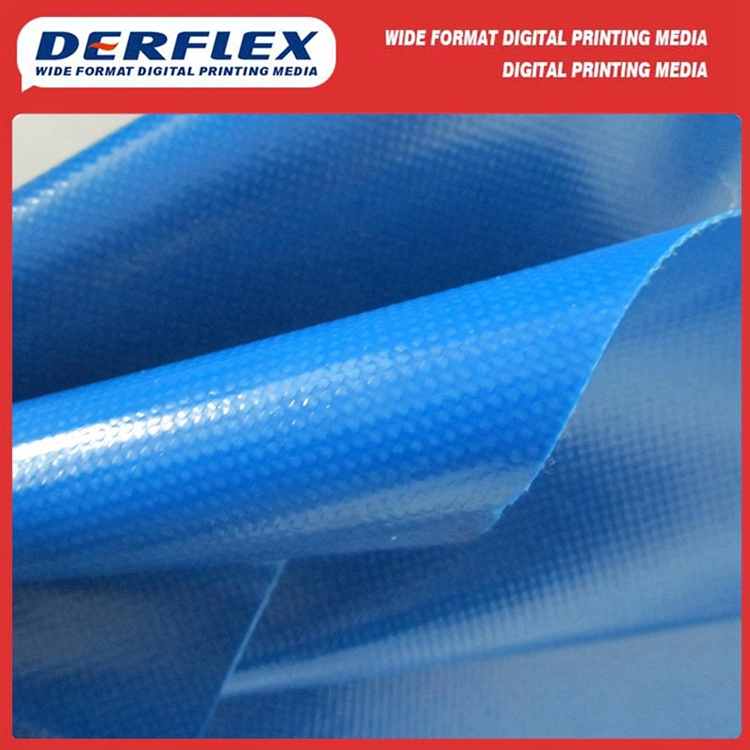

Additionally, selecting high-quality PVC tarpaulin that meets specific requirements can ensure better durability and anti-aging performance. The quality and performance of PVC tarpaulin are influenced by the choice and use of PVC raw materials, additives, and the base fabric quality. Properly selecting high-quality raw materials, appropriate additives, and combining them with superior base fabric can manufacture PVC coated tarpaulin with excellent performance and durability.

The quality of PVC tarpaulin is closely related to the PVC raw materials, additives, and base fabric used. PVC raw material quality: The quality of PVC tarp is significantly affected by the quality of the PVC raw materials used in manufacturing. High-quality PVC raw materials exhibit good stability, durability, and anti-aging properties, which directly impact the tarpaulin's durability and service life.

Role of additives: Additives play a crucial role in PVC manufacturing, improving PVC characteristics. For example, stabilizers can slow down the aging process of PVC materials; plasticizers can enhance PVC flexibility, and antioxidants can reduce the oxidation effects on PVC materials when exposed to the environment. Correctly selecting and using these additives can enhance the quality and performance of PVC tarpaulin.

Base fabric quality: Tarpaulins are typically made by coating PVC material onto a base fabric. The quality and performance of the base fabric are crucial for the tarpaulin's durability and strength. High-quality base fabric can enhance the tarpaulin's abrasion resistance and tensile strength, making it more suitable for different environments and applications.

Choose reputable brands or manufacturers. Well-known brands usually uphold higher quality standards and stricter quality control, providing more reliable products. Anhui Der New Material Technology Co., Ltd. has been engaged in the production and sale of PVC products for over twenty years, with four professional factories in China. Our new factory is located in the Polymer Industry Park in Chuzhou, Anhui Province, covering an area of over 30,000 square meters. We have invested $30 million in purchasing five laminating machines capable of producing materials with a maximum width of 5.1 meters. With nine coating and laminating production lines, we can produce 10 million square meters per month, holding 13 technology monopolies, and our product quality complies with EU standards.

Previous:What is CANVAS

Next:The factors influencing the price of tarpaulin

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.