PVC Tarpaulin for Agriculture..

- 2025-12-17

I. Product introduction

The production of membrane structure materials for commercial facilities involves many links. The following is a brief introduction to its materials, production processes, advantages and uses:

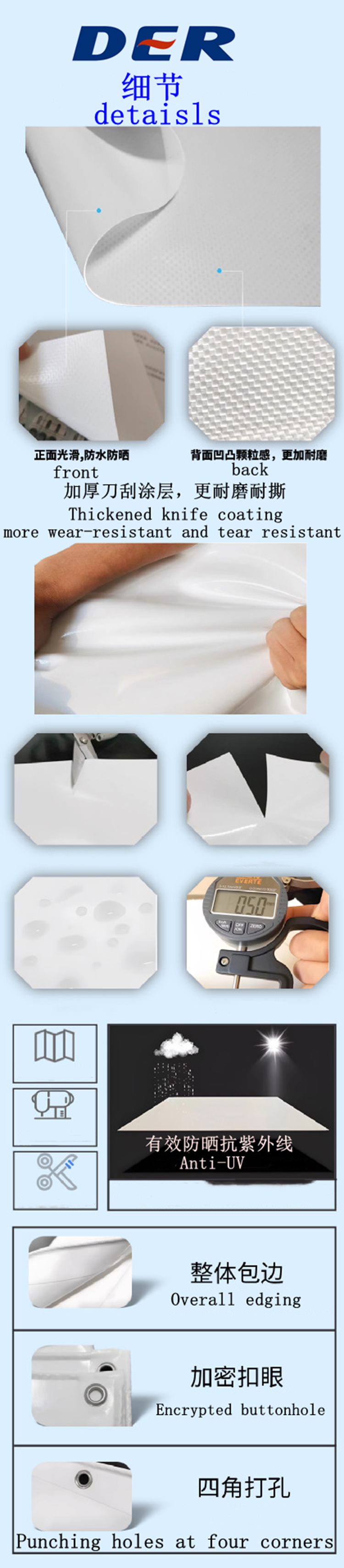

Materials: Membrane structure materials for commercial facilities are mainly composed of base fabric and coating. The base fabric often uses polyester fiber and fiberglass materials, while the coating mainly uses polyvinyl chloride (PVC) and polytetrafluoroethylene (PTFE). Polyester fiber-coated polyvinyl chloride (PVC) material has the characteristics of low price, easy processing, and rich colors, but its strength and durability are relatively low. The glass fiber-coated polytetrafluoroethylene (Teflon) material has high strength, high durability and good self-cleaning properties, but the price is higher.

Production process: The production of membrane materials mainly includes the following steps: First, material preparation is carried out, including screening, proportioning, mixing and crushing. Next, through a coating process, the material solution is evenly applied to the substrate and then dried into a thin film. Later, a lamination process may be performed to combine the membrane with other materials. During the entire production process, attention needs to be paid to controlling the coating technology, drying temperature, and composite parameters to ensure the quality and performance of the membrane material. The above is only a brief overview, and the specific production process may vary depending on the material and application area.

Advantages: Membrane structural materials for commercial facilities have the advantages of wear resistance, tear resistance, durability, high temperature resistance, wind protection, rain protection, sunshade, fire protection, waterproof, sun protection, lightness and beauty, energy saving and environmental protection, and easy cleaning. Its lightness reduces the weight of the building and reduces the pressure on the foundation; its good light transmittance and thermal insulation properties help reduce energy consumption; and its easy-to-clean feature keeps the appearance of the building neat and beautiful.

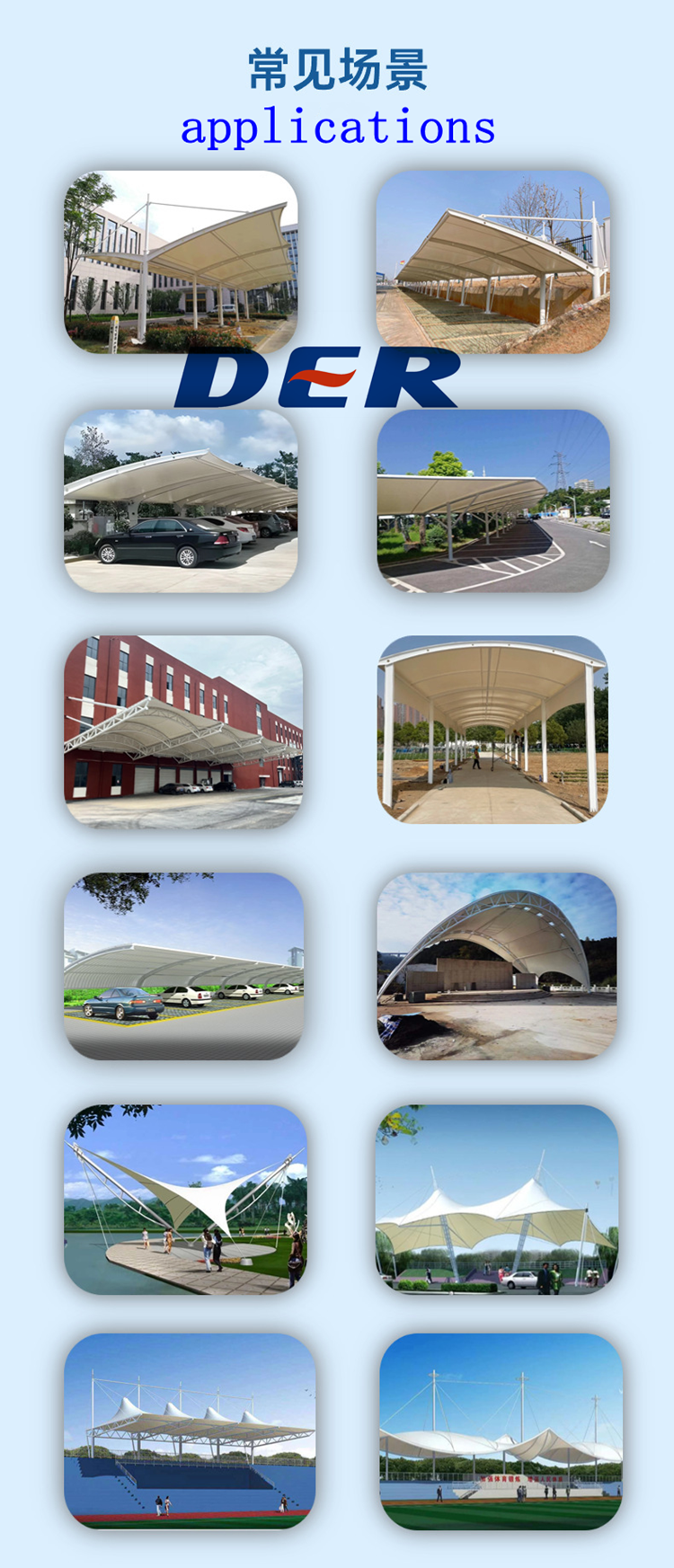

Usage: Membrane structure materials for commercial facilities are widely used in various construction fields, such as shopping malls, exhibition halls, sports venues, etc. For example, the use of membrane structure materials on the roof of shopping malls can form an architectural shape with graceful curves, and at the same time have good energy-saving and environmental protection performance; exhibition halls and sports venues can use the long-span characteristics of membrane structure materials to create column-free spaces to meet special needs. Usage requirements. In addition, membrane structure materials can also be used for sun and rain protection facilities to provide a dry and comfortable environment for cargo and pedestrians.

II. Product Specifications

1. Fabric specifications

|

Product name |

Membrane structural materials for commercial facilities |

|

Product color |

custom |

|

Product material |

Mesh+PVC coating |

|

Yarn quantity |

1000D*1000D |

|

Product thickness |

0.8MM |

|

Product density |

30*30 |

|

Fabric width |

2.5-3.2M |

|

Product weight |

1050gsm |

|

Product Features |

Thickened and wear-resistant, flexible and easy to fold, tear-resistant and tensile-resistant, waterproof, environmentally friendly, and odorless |

|

Waterproof index |

99.99% |

|

Use life |

more than 10 years |

|

Product usage |

Widely used in various construction fields, such as shopping malls, exhibition halls, and sports venues |

|

Product size |

custom |

2. Accessories: welding, buttonholes, hemming

3. Product size: customized

4. Comparison of product advantages and disadvantages

Compared with ordinary tarpaulin, membrane structure

Lightweight and high-strength: The membrane structure is made of lightweight materials. The structure is light in weight and has high strength and rigidity. It can remain intact in harsh climates such as strong winds and heavy snow.

Flexible shape: The membrane structure has greater flexibility and freedom in shape and can be customized according to customer needs. It also has excellent light transmittance, creating a more comfortable indoor space for the architectural environment.

Large span: The membrane structure is light in weight and has good seismic resistance. It does not require internal supports, creates a huge unobstructed visible space, and effectively increases the space usage area.

Artistry: Membrane structure breaks through the traditional building structure types. Relying on modeling and color science, it can create curves and various shapes that are difficult to achieve in traditional buildings. It is rich in color and full of the flavor of the times.

Economical: The membrane material has a certain light transmittance, which can reduce lighting intensity and time during the day and save energy; the transmission of colored lights at night can form a gorgeous landscape. Moreover, the membrane structure can be disassembled and easily relocated, which is more economical especially when building long-span buildings for short-term applications.

Safety: The membrane material has excellent flame retardancy and high temperature resistance, which can well meet the fire protection requirements; the membrane structure is a flexible structure, can withstand large displacements, and is not prone to overall collapse; the membrane structure is light in weight and has relatively good earthquake resistance.

Ordinary tarpaulin

Limited thermal insulation effect: Compared with professional thermal insulation materials, the thermal insulation effect of tarpaulin is not very ideal because its shading area is relatively small, and this kind of shading material is mainly suitable for outdoor use, and the indoor thermal insulation effect is relatively poor. .

Limited shape: Compared with membrane structures, ordinary tarpaulins are more limited in shape, making it difficult to achieve complex curves and shapes.

III. Product application

IV.Company Profile

Anhui Yaen New Material Co., Ltd. is one of the leading heavy-duty PVC coated tarpaulin manufacturers in China with over 20 years of experience. Since 1997, we have been dedicated to researching, developing and manufacturing tarpaulin products. We have a large number of advanced equipment, scientific management, first-class technology, continuous design and professional team to meet market demand in a timely manner. As a professional PVC tarpaulin manufacturer with more than 20 years of production and sales experience. We have 2 knife coating production lines, 4 calendering machines, and 8 laminating machines to produce double-layer and coated PVC tarpaulin materials suitable for various fields. We are a high-tech industrial company certified by Zhejiang and Anhui provinces, and have won the National Technology Progress Award. Now, we have 8 PhDs, 23 graduate students, and many employees with undergraduate degrees for improving and developing new products and production processes, which ensures DER as a growing coated fabric company.

Anhui DER New Material Technology Co., Ltd

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.

Message