PVC Tarpaulin for Agriculture..

- 2025-12-17

In the fields of entertainment and sports, PVC trampoline fabric has been widely used due to its unique advantages. This material is not only durable but also has good elasticity and safety, making it the preferred material for trampoline manufacturing. This article will delve into the advantages, usage scenarios, benefits, and manufacturing process of PVC trampoline fabric.

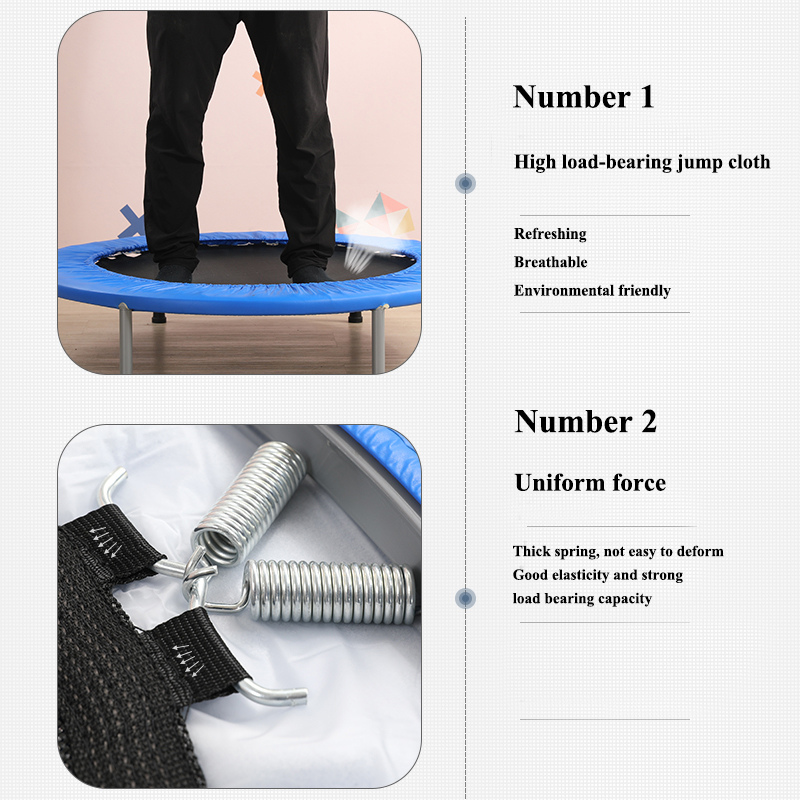

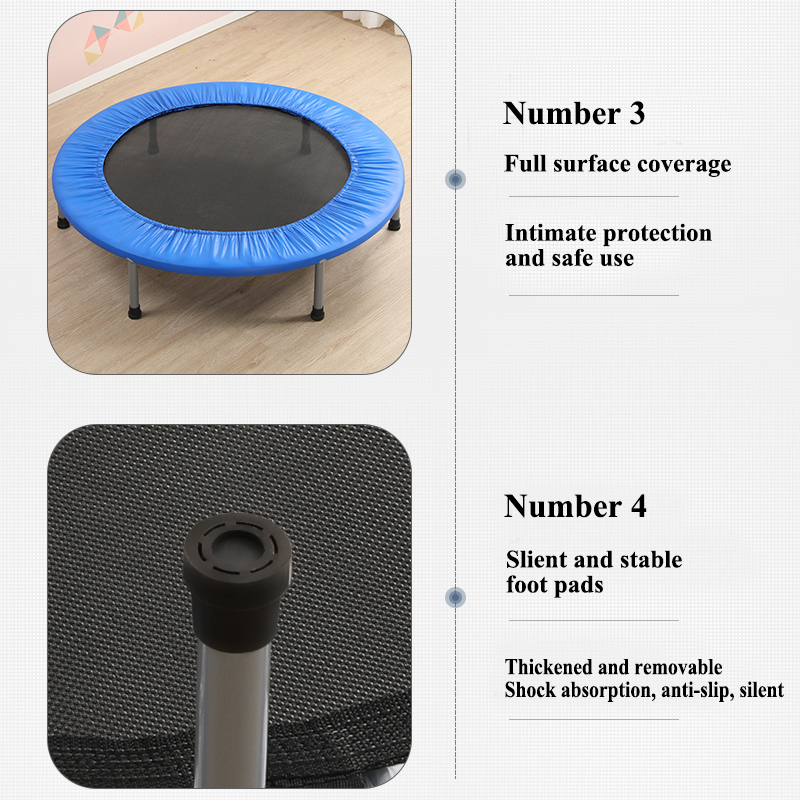

Advantages of PVC Trampoline Fabric

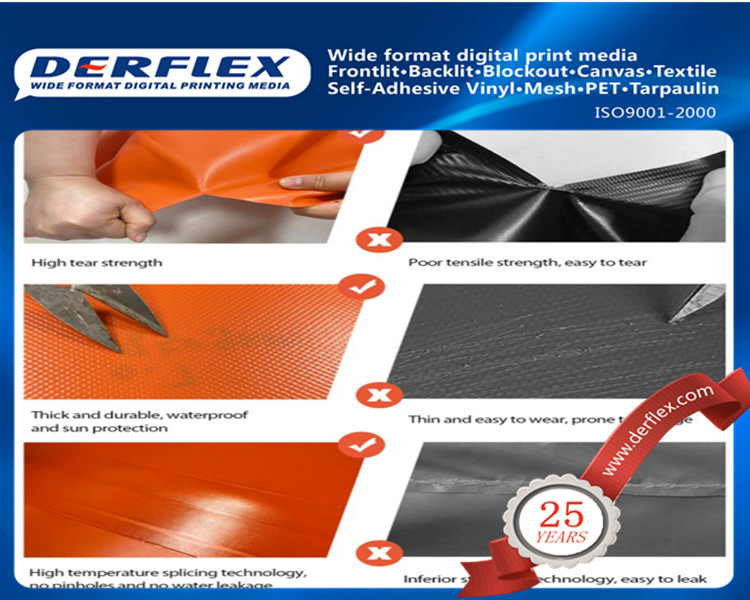

Durability: PVC trampoline fabric is made from high-quality PVC material, which exhibits excellent wear resistance, tear resistance, and aging resistance. It can withstand frequent use and heavy pressure without easily damaging.

Elasticity: PVC trampoline fabric possesses good elasticity, providing users with a superior bouncing experience. Additionally, its high elastic recovery rate ensures long-lasting elasticity and resistance to deformation.

Safety: PVC trampoline fabric has a smooth surface with low friction, minimizing the risk of injury during jumping. Moreover, its flame-retardant properties effectively prevent fire accidents.

Usage Scenarios of PVC Trampoline Fabric

Amusement Parks: PVC trampoline fabric is widely used in indoor and outdoor amusement parks, providing children and young adults with a fun and challenging bouncing experience.

Gyms: In gyms, PVC trampoline fabric is utilized as an aerobic exercise equipment, aiding individuals in physical training and improving their cardiovascular health.

Home Entertainment: PVC trampoline fabric is also suitable for home use, offering a fun and relaxing entertainment option for family members and enhancing parent-child relationships.

Benefits of PVC Trampoline Fabric

Wide Applicability: PVC trampoline fabric is suitable for various occasions and age groups, catering to the needs of different individuals.

Easy Installation: The installation process of PVC trampoline fabric is simple and quick, requiring no complex equipment or tools, thus reducing installation costs.

Convenient Maintenance: PVC trampoline fabric is easy to clean and maintain. Regular wiping and inspection can keep it in good condition.

Manufacturing Process of PVC Trampoline Fabric

Material Preparation: High-quality PVC raw materials are selected and undergo strict screening and testing to ensure their quality meets the required standards.

Cutting and Sewing: According to design requirements and size specifications, the PVC raw materials are cut and sewn to ensure the overall structure and dimensions of the trampoline fabric are accurate.

Coating and Heat Sealing: A special wear-resistant and anti-slip coating is applied to the surface of the PVC material to enhance the service life and safety of the trampoline fabric. Subsequently, various parts are securely connected through heat sealing to form a complete trampoline fabric.

Quality Inspection: Strict quality inspections are conducted on the manufactured PVC trampoline fabric, including dimension checks, elasticity tests, and flame retardancy tests, to ensure the product meets relevant standards and requirements.

Packaging and Shipping: After passing the inspections, the PVC trampoline fabric is packaged with product information and safety warnings, and then sent to various sales channels for consumers to purchase and use.

In conclusion, PVC trampoline fabric, with its advantages, wide range of usage scenarios, significant benefits, and meticulous manufacturing process, has become an essential component in modern entertainment and sports fields. With continuous advancements in technology and changing consumer demands, PVC trampoline fabric will continue to innovate in materials, design, and functionality, providing people with a more superior, safe, and enjoyable bouncing experience.

Product specifications:

|

Product name |

38 inches trampoline |

48 inches trampoline |

60 inches trampoline |

|

Diameter |

96cm (0.96 meters) |

121cm (1.21 meters) |

152cm (1.52 meters) |

|

Number of springs |

32 |

40 |

48 |

|

Folding method |

four fold |

two fold |

two fold |

|

Expand Size |

96*96*22cm |

121*121*27cm |

152*152*27cm |

|

Package Size |

77*37*10cm |

124*67*9.5cm |

155*83*9.5cm |

|

Load bearing |

100KG |

160KG |

200KG |

|

Product weight |

9KG |

11KG |

15KG |

|

Number of legs |

8 roots |

8 roots |

10 roots |

Finished product size

Customizable

Comparison of product advantages and disadvantages

Finished product display

Anhui DER New Material Technology Co., Ltd, Located in Zhangbaling Industrial Zone Mingguang City, Chuzhou City, Anhui Province, is a professional manufacturer for PVC tarpaulin, PVC membrane, TPU coated fabric, sun screen fabrics, super clear PVC film swimming pool liner. Knife coating, hot-melting productions for OEM production on different thickness and softness functional products.; Virous product categories and competitive price, which is popular exported to more than 100 countries all over the world.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.

Message