PVC Tarpaulin for Agriculture..

- 2025-12-17

The fabric of tarpaulin material, widely utilized in various fields such as PVC tents, truck covers, and the construction industry due to its durability, waterproofing, and UV resistant characteristics, is influenced by multiple factors in terms of pricing. This reflects the diverse features and extensive applications of PVC vinyl tarpaulin.

In terms of raw materials, the most expensive component is additives. The higher the proportion of plasticizers, the softer the material, resulting in a relatively higher price. The quality of plasticizers also varies, and the price is influenced by different climatic conditions. For example, in colder regions, more plasticizers may be added to make the fabric relatively softer. The calcium powder content also affects the price of tarpaulin; as calcium powder is cheaper than PVC, it explains the presence of many low-priced PVC tarpaulins in the market.

Color is another factor influencing tarpaulin prices. Fabrics manufactured with common pigments tend to fade quickly during use. Our factory uses imported pigments, allowing customization of colors such as bright red, metallic, and fluorescent, ensuring the fabric remains fade-resistant during outdoor use.

Apart from raw material costs, machine speed also impacts prices. Normal production yields 14-15 meters per minute. Higher quality requirements result in more frequent inspections, leading to increased labor costs, lower output, and consequently higher prices. The thickness of the tarpaulin also influences the drying time, with thicker materials requiring longer drying times and, consequently, higher prices.

We can also incorporate customer-specific requirements, such as UV inhibitors, flame retardants (B1/NFPA701/M1/M2), anti-static agents, cold-resistant agents, etc. Many PVC duct fabrics used in mining applications commonly feature anti-static tarpaulin.

PVC fireproof doors often utilize PVC flame retardant tarp

DER is the leading manufacturer in China focusing on industrial fabrics and films since 1997.

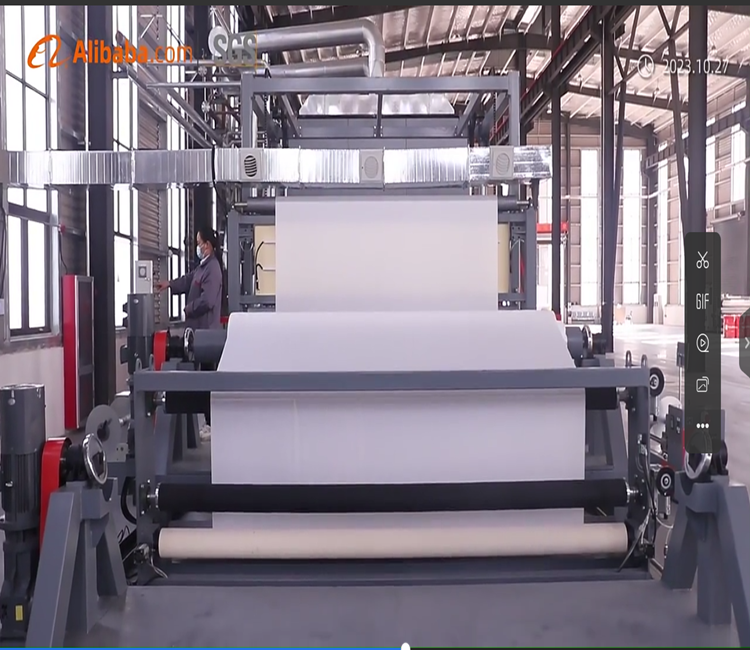

50 knitting machines and weaving machines,3 calendars, 4 coating machine, 25 senior engineers and 450 workers make our factory more competitive among the PVC coated fabric supplies.

DER has whole series of QC system. At the same time, we cooperate with East China University Science and Technology, which is famous University in China, to build polymeric exploring lab.

Our customers are spread across more than 100 countries. We track all orders from the purchase order, production, shipping, to after-sales service.

All orders undergo rigorous quality control to meet customer requirements.

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.