PVC Tarpaulin for Agriculture..

- 2025-12-17

Thermoplastic polyurethanes (TPU) are very versatile materials and are widely used in manufacturing storage tanks, inflatables, life jackets, medical devices and many more applications.

Polyester and polyether are the two major varieties of polyurethane available along with a smaller class known as polycaprolactone. TPU can be further subdivided into Aliphatic and Aromatic TPU’s.

Both polyester urethane and polyether urethane are elastomers, a combination of the words elastic and polymer, which means they have elastic properties and have distinct polymer performance characteristics. Both types of composition have advantages and limitations and are appropriate for different applications. While Polyether TPUs offer good flexibility at low temperatures and hydrolysis, Polyester TPUs offer high chemical and oil resistance. Choosing the right grade of TPU with a good understanding of its chemical composition can greatly affect the functionality and lifespan of your product.

Polyurethanes is a multi-phase block co-polymer made by a chemical reaction between a polyol and disocyanate using a chain extender. The soft block (polyol) is responsible for the flexibility and elastomeric character of TPU while the hard block (disocyanate) gives the toughness and physical performance properties.

Small changes in the chemistry dictate how the TPU behaves, polyester TPU are made from polyols that contain ester groups, leading to excellent abrasion and chemical resistance and superior tensile strength and are also compatible with polar plastics like PVC. Polyether TPU’s made from polyols containing ether groups which impart excellent hydrolysis and microbial resistance along with outstanding low temperature resistance.

Aromatic and Aliphatic grades of TPU refer to changes made to the diisocyanate section of the TPU, where Aromatics are the most commonly available, having good abrasion resistance and tensile strength. Aliphatic grades have excellent clarity and won’t oxidize under UV radiation and don’t turn yellow, therefore they are used mostly in clear and/or outdoor applications.

How to choose Ester and Ether Polyurethanes

When selecting the grade of TPU for an application, one should consider the environment where it will be used, operational and environmental temperatures, indoor or outdoor, chemical, and mechanical stress on the material, to what additional material does it need to adhere, are some of the key questions that will help narrow down the search. While polyester and polyether polyurethanes have similar durometer ranges, they have many major differences, below are some of the specific differences between the two:

Changing the distribution of the hard and soft segments will impart different properties to the TPU, we will look at some of the Specific Properties for both types of TPU’s

Abrasion Resistance Properties

Urethanes have excellent abrasion resistance. They have far greater wear resistance than metals, plastics, and other rubbers. Abrasion resistance comes in two forms: sliding and impingement. Impingement refers to particles or things striking the urethane surface at a high angle, whereas sliding refers to scraping and rubbing abrasion.

Chemical, Grease, Fuel, Solvent, Water and Chemical Resistance

If the TPU is in a high humidity environment or is submerged or constantly exposed to water, polyether urethane is an excellent choice because of the hydrolytic stability. Polyether TPU also has good microorganism resistance.

Whereas if the product comes in contact with oils, fuels solvents, Polyester urethane provide excellent resistance from harsh chemicals making it ideal for CIPP liners, Storage tanks.

High and Low Temperature resistance

Mechanical Properties

From a price point, Polyether’s are more expensive than Polyester as the polyol that form the soft segment of a Polyether is generally priced higher on raw materials and is more complicated and difficult to produce, requiring advanced equipment. Also, being better in hydrolytic and low temperature resistance the demand is much higher for Polyether based TPU.

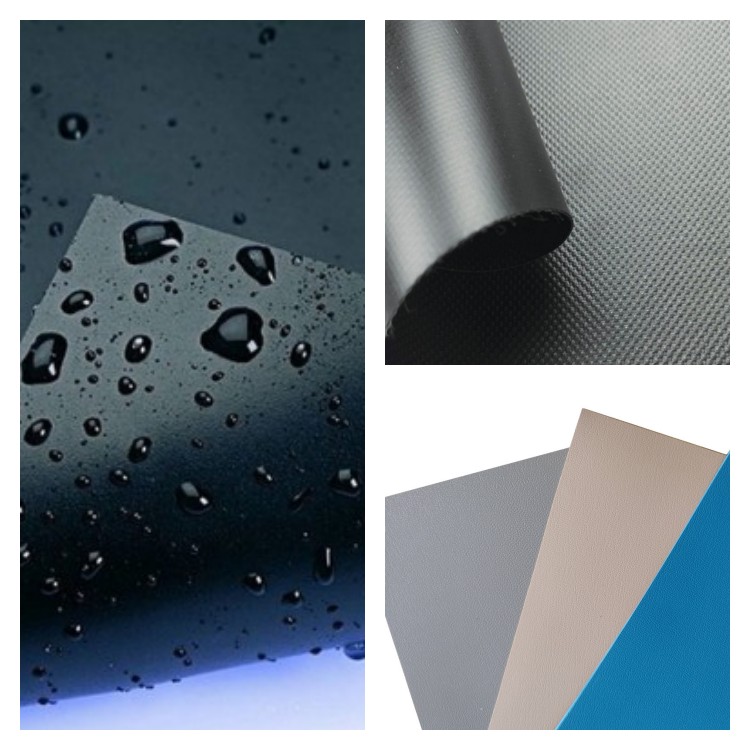

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.