PVC Tarpaulin for Agriculture..

- 2025-12-17

I. Product Introduction

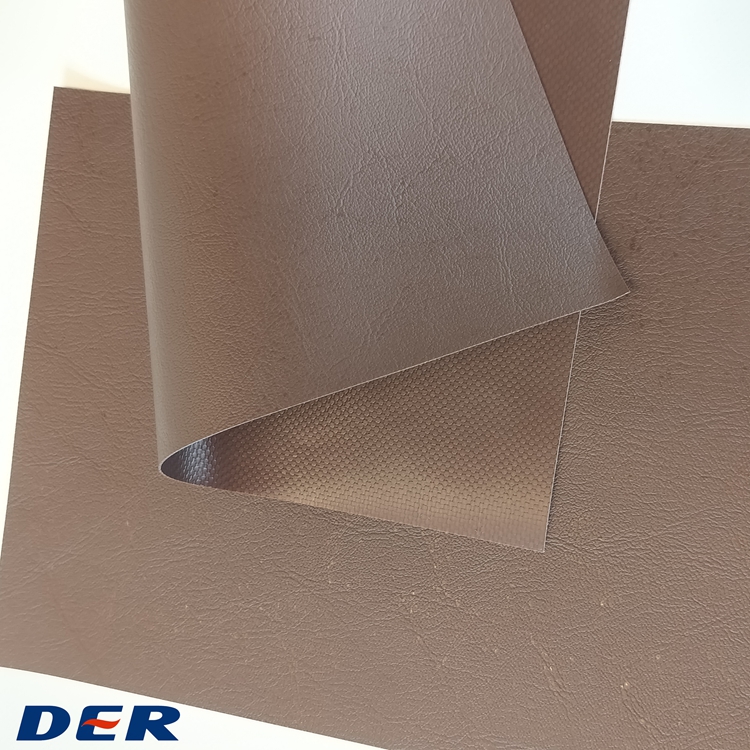

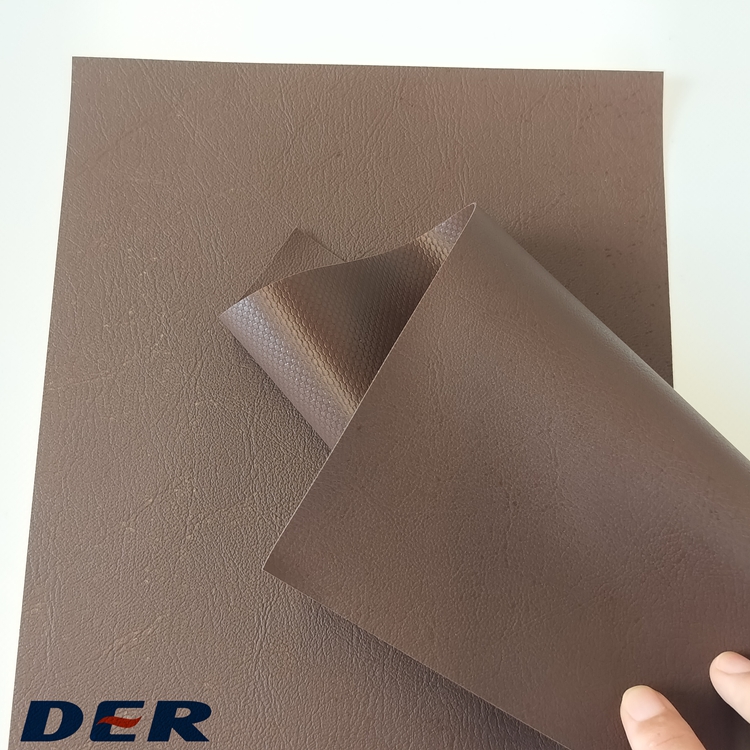

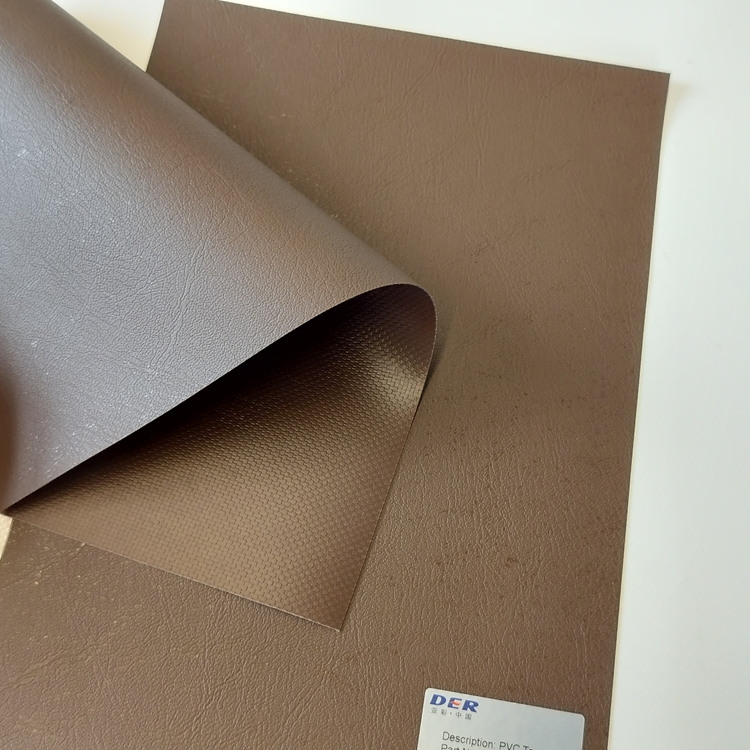

1. Leather grain tarpaulins utilize a high-strength polyester mesh as the base fabric, with a high warp and weft density providing excellent tear resistance. The surface is coated with a double layer of PVC, with a total thickness of 0.5-0.8mm. The inner PVC layer enhances toughness, while the outer layer is specially formulated to create a leather-like feel.

2. Waterproof leather grain tarpaulins are embossed using a high-temperature, high-pressure embossing process, laser-engraving a leather texture onto the PVC surface, creating a three-dimensional lychee, crocodile, or matte effect. Some high-end products utilize a triple embossing process, layering patterns of varying depths to simulate the layered texture of natural leather.

3. Self-cleaning Coating: Leather grain tarpaulins are sprayed with ACRYLIC or PVDF nanomaterials, reducing dust adhesion by 70% and remaining clean even after washing away with rain.

4. Composite Protection: The addition of hindered amine light stabilizers (HALS) and antimicrobial agents provides UV resistance (UV50+), 99% antibacterial efficiency, and acid and alkali resistance (pH 2-12).

II. Product Features

Weatherproof: Temperature-resistant from -40°C to 70°C, it can withstand 12 hours of continuous heavy rain (3000mm hydrostatic pressure) and 80km/h winds, making it suitable for complex climates such as the Mexican rainy season and the extreme cold of Northern Europe.

Long-lasting durability: Anti-aging properties demonstrated by 3000 hours of QUV testing with a tensile strength retention rate exceeding 85%, resulting in a service life of 5-7 years, over three times that of ordinary tarpaulins.

Simulated leather texture: With a clear texture and delicate touch, it can replace traditional leather for high-end outdoor furniture and exhibition decorations, enhancing the style of any space.

Multi-scene adaptability: The transparent version offers 80% light transmittance, promoting crop photosynthesis; the blackout version can reduce ambient temperature by 5°C, making it suitable for greenhouses and warehouses.

Customization available (color, texture, thickness, and size) to meet individual needs.

Abrasion and scratch resistance: More resistant to abrasion than ordinary tarpaulins, suitable for frequent use or outdoor environments.

Tear resistance: The base fabric (such as Oxford cloth or polyester) is combined with a PVC/PU coating for enhanced strength.

III. Product Applications

Outdoor Applications: Car covers, awnings, camping tents, etc., combining protection and aesthetics.

Commercial Applications: Exhibition backdrops, store decorations, and furniture dust covers enhance visual quality.

Industrial Applications: Warehouse tarpaulins and equipment covers, balancing durability and appearance.

Logistics and Transportation

Cargo Protection: Leather grained tarpaulins used on truck covers protect grain and building materials from moisture and mildew during transportation, reducing cargo damage by over 65%.

Cold Chain Optimization: Refrigerated truck models with integrated phase change energy storage materials maintain a constant temperature between -20°C and 40°C, reducing energy consumption by 25%.

Construction and Engineering

Site Protection: B1 flame-retardant tarpaulins can cover welding areas, withstand 300°C welding slag splash, and mitigate fire risks.

Temporary Facilities: Modular tents withstand wind speeds of up to 800°C, making them suitable for exhibitions and emergency rescue operations, and install in just 15 minutes. Agriculture and Ecology

Crop Protection: Antibacterial and mildew-resistant tarpaulins reduce fruit rot during storage and extend the shelf life of grains like corn by three months.

Eco-Friendly Farming: Translucent and breathable versions are used in farms to enhance natural light and ventilation in poultry areas.

Outdoor and Living

High-End Applications: Faux leather-patterned tarpaulins are used for wedding awnings and yacht deck decorations, and custom logos can enhance brand image.

Everyday Uses: Lightweight versions (300g/㎡) can be used as pet beds and foldable water buckets, ensuring both portability and durability.

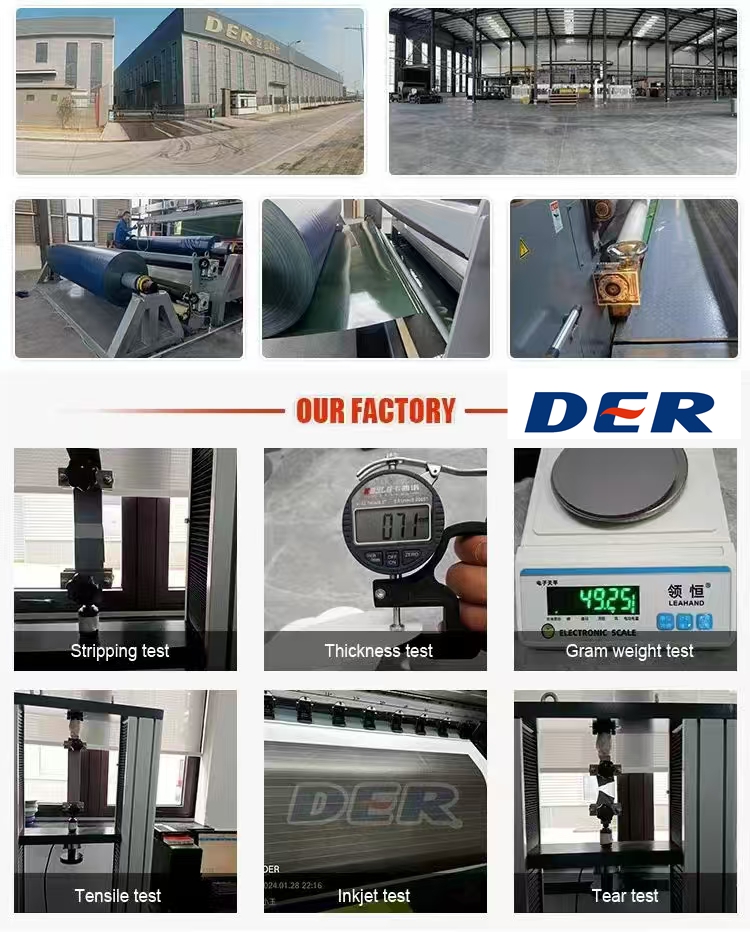

IV. Company Profile

Anhui DER New Materials Co., Ltd. is one of China's leading heavy-duty PVC coated tarpaulin manufacturers, with over 20 years of experience. Since 1997, we have been dedicated to the research, development, and manufacturing of tarpaulin products. We utilize a wealth of advanced equipment, scientific management, top-notch technology, continuous design, and a dedicated team to meet market demands promptly. As a professional PVC tarpaulin manufacturer, we have over 20 years of experience in production and sales. We have two knife-coating lines, four calenders, and eight laminating machines, producing double-layer and coated PVC tarpaulin materials for a variety of applications. We are a certified high-tech industrial company in both Zhejiang and Anhui provinces and have received the National Technological Progress Award. We currently employ eight PhDs, 23 graduate students, and numerous employees with bachelor's degrees, dedicated to improving and developing new products and production processes, ensuring DER's continued success as a leading coated fabric company.

For more information,pls contact ElaineZhang

TEL:(+86)199 5504 7834(Wechat/(Whatsapp)

E-mail:Elaine@der-factory.com

Web: www.der-factory.com/en

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.