PVC Tarpaulin for Agriculture..

- 2025-12-17

Below is a polished content draft for PVC-Coated Polyester Fabric from Anhui DER New Materials / DERFLEX, following your requested structure. You can adapt or expand it as needed.

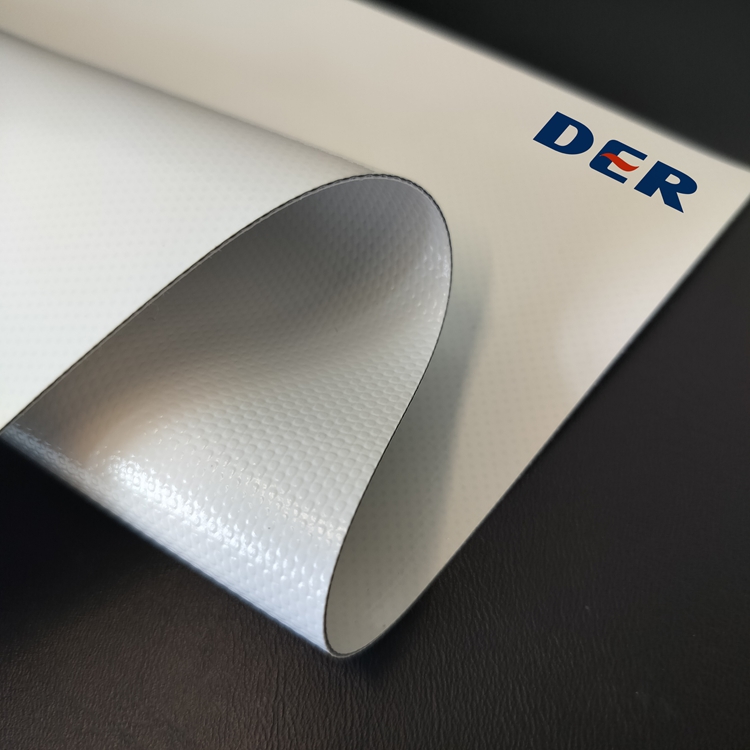

PVC-Coated Polyester Fabric Manufacturer

Product Introduction

PVC-coated polyester fabric is a composite textile made of a woven polyester scrim (or base fabric) which is then coated, laminated, or impregnated with a polyvinyl chloride (PVC) formulation. The polyester provides tensile strength, stability, and tear resistance; the PVC coating gives surface properties such as waterproofing, UV resistance, and durability. This type of fabric is widely used in heavy-duty industrial and architectural applications where flexibility, strength, and weather resistance are required.

At Anhui DER New Materials / DERFLEX, we produce PVC-coated polyester fabrics with various weights, coatings, finishes, and performance treatments to meet demanding specifications for outdoor, industrial, and architectural uses.

Product Features

Here are the key advantages and technical attributes of DER’s PVC-coated polyester fabrics:

High strength & dimensional stability — The polyester substrate ensures excellent tensile strength, low stretch, and resistance to distortion.

Waterproof / impermeable — The PVC coating forms a continuous film that blocks water infiltration.

Weather / UV resistance — With additives (UV stabilizers, HALS agents) in the PVC layer, the fabric can withstand prolonged exposure to sunlight and outdoor conditions.

Flame retardancy — Formulations can meet fire safety standards (e.g. B1, B2, M1) depending on customer requirements.

Surface finish variety — Glossy, semi-glossy, matte, or textured surfaces (lacquered, acrylic topcoats).

Anti-mildew / anti-fungus — By adding biocides or fungicides to resist growth in humid environments.

Cold crack / low temperature flexibility — Maintains integrity at subzero temperatures (depending on formulation).

Tear & rupture resistance — The composite structure provides strong resistance to punctures, tears, and abrasions.

Good adhesion / weldability — Compatible with heat welding, RF welding, or hot-air welding for joining and fabrication.

Customizability — Weight (from ~300 g/m² up to 1,500 g/m² or more), width, color, coating thickness, patterns, and additives can be tailored.

Because PVC-coated polyester fabric is a hybrid material, you get the mechanical robustness of a woven textile + the barrier and finishing properties of a plastic coating.

Product Applications

PVC-coated polyester fabrics from DER are used across many sectors, including:

Tents & membranes — Acrobatic tents, circus tents, exhibition halls, marquees.

Tarpaulins / covers — Truck tarps, truck side curtains, container covers, canopy covers, shielding covers. ([Alibaba.com][4])

Architectural membranes & facades — Tensile fabric structures, membrane roofs, awnings, shaded canopies. ([dertarpaulin.com][5])

Inflatables & air structures — Inflatable advertising towers, bounce houses, air domes.

Industrial covers & shelters — Temporary shelter membranes, heavy machinery covers, environmental enclosures.

Pool liners / pond membranes — Waterproof lining for aquatic applications (depending on formulation).

Advertising, banners, and signage textiles — When a textile substrate is required behind a printable vinyl or digital print surface.

Other specialty uses — e.g. containment covers, dust shields, agricultural covers, flexible partitions.

Because of its strength and durability, the PVC-coated polyester fabric is especially favored where a combination of flexibility, weatherability, and long service life is needed.

Anhui DER New Materials / DERFLEX Company Profile

Here’s a company profile focused on their capabilities in coated fabrics:

Name: Anhui DER New Material Technology Co., Ltd. (also operates under DER / DERFLEX brand)

Location / Factory: Zhangbaling Industrial Zone, Mingguang City, Chuzhou, Anhui Province, China. ([Alibaba.com][4])

Business scope: Manufacturing and exporting PVC tarpaulin, PVC coated fabrics, architectural membranes, transparent PVC films, TPU fabrics, and related technical textiles.

Production capability & processes: Operates multiple coating lines (knife coating, hot melt, lamination) and calendaring equipment.

Experience & R&D: Over 20+ years in the industry (or claims thereof) with emphasis on material innovation. ([derflex-sign.com][7])

Quality control & certification: Committed to rigorous testing, offering different performance reports to clients. (Though I did not find specific ISO certificates in the sources, that is often standard in this field.)

Export markets: DER exports to more than 100 countries globally, including Europe, North America, South America, Africa, Middle East, and Asia.

Core values / positioning: Focus on durability, custom performance, and promoting advanced coated textile solutions.

Installation / Fabrication Precautions

To ensure optimal performance and longevity, here are installation and handling recommendations:

1. Surface preparation & cleanliness

Make sure the substrate or frame is clean, smooth, and free from sharp edges or protuberances.

Remove dust, oils, or residues before bonding or welding.

2. Cutting & edge preparation

Use sharp, proper cutting tools (rotary cutters, hot knives) to avoid fraying or delamination.

Seal cut edges (if needed) with compatible sealants or heat treatment to prevent ingress of moisture.

3. Joining & welding

Employ appropriate welding techniques — hot-air welding, RF welding, or hot-melt adhesive — suited to the PVC formula.

Ensure optimal heat, speed, and pressure settings to achieve full bond without damaging the fabric.

For seams, allow a margin beyond overlap to accommodate shrinkage.

4. Anchoring and fastening

Use grommets, ropes, tapes, or bead rails as per design. Ensure force distribution so as not to overstress the fabric.

Avoid point loads; use spreaders or patches to reduce stress concentration.

5. Thermal expansion / contraction allowance

Consider fabric expansion under heat (sunlight) and contraction under cold; design slack or curves accordingly.

Avoid rigid fixing that may cause puckering or stress.

6. Avoid mechanical damage

Prevent sharp or abrasive contact with edges or hardware.

In transportation, roll (not fold) the fabric to reduce crease formation.

7. Proper tensioning

Apply uniform tension to avoid sagging but not over-tight to cause undue stress.

Gradual tension release in cold weather is recommended.

8. Storage

Store rolls horizontally or upright with proper core supports.

Keep in dry, ventilated, rodent-free environment, away from sources of heat or UV exposure.

Avoid long-term exposure to sunlight before installation.

9. Inspection & maintenance

Inspect periodically (seams, edges, anchor zones) for damage or degradation.

Repair minor damage promptly using patch kits or compatible welding.

By adhering to these precautions, the fabric can be installed reliably and maintain performance over its expected lifetime.

Sold-to Countries / Export Markets

DER / DERFLEX claims a broad global footprint. Some of the known export markets include:

Europe (UK, Germany, France, Italy, Russia, etc.)

North America (USA, Canada)

South America (Brazil, Argentina, etc.)

Africa & Middle East (South Africa, Nigeria, Kenya, UAE, Saudi Arabia, etc.)

Asia & Oceania (Japan, Korea, India, Australia, etc.)

Thus, their coated fabrics are marketed widely across all populated continents.

Use FAQs

Q1: What weight (gsm) ranges are typical for PVC-coated polyester fabrics?

DER’s products cover a broad range — commonly from 300 g/m² up to 1,500 g/m² or more, depending on required strength and durability.

Q2: Can these fabrics be used outdoors long-term?

Yes. With proper UV stabilizers, weather-resistant coatings, and good installation, they can serve outdoors for many years under normal environmental conditions.

Q3: Are they fire retardant?

Yes, formulations can meet different retardancy levels (B1, B2, M1, etc.), depending on customer needs.

Q4: What is “cold crack” performance?

Cold crack refers to the temperature below which the PVC becomes brittle and may crack. DER’s specialized formulations maintain flexibility to certain low temperatures (e.g. –20 °C or lower).

Q5: How are seams joined?

Typically by hot-air welding, RF welding, or compatible heat-sealing techniques. Proper control of heat, pressure, and speed ensures good seam integrity.

Q6: Is customization possible?

Yes — color, coating thickness, surface finish, pattern embossing, additives (anti-fungal, anti-static, UV, scratch resistance), width, and weight can all be tailored.

Q7: How should the fabric be shipped & packed?

Usually rolled onto cores, wrapped (e.g. Kraft paper or PE film), sometimes protected with tubes or edge guards.

Q8: What is the expected outdoor life?

It depends on formulation, location, and exposure. Under favorable conditions with good UV stabilization, service life of 5 to 10 years (or more) is possible.

Relevant Keywords

Here are SEO / industry keywords to include:

PVC coated polyester fabric

Polyester PVC coated textile

PVC coated polyester tarpaulin

DERFLEX coated fabric

PVC coated polyester membrane

PVC coated fabric manufacturer

Heavy duty coated polyester

Waterproof PVC coated textile

PVC coated fabric for tents

Architectural membrane fabric

UV resistant PVC coated fabric

Flame-retardant coated polyester

PVC coated polyester canvas

Our products are widely used in our residential and industrial area, which can be used for producing tents, outdoor covering, flexible ventilation tube, water bladders, inflatable castles, architecture membrane structures, etc. Our main products: PVC coated fabrics, PU/TPU coated fabrics, Oxford fabric, PVC ceiling film, flexible banner material. Welcome to our site and order online.