DER New Material is a professional tarpaulin manufacturer in China, offering a full range of high-performance PVC and PE tarpaulins for truck covers, tents, agricultural uses, industrial shelters, silage films and custom applications. We combine modern coating and lamination lines, digital printing, precision cutting and welding to deliver consistent, certified tarpaulin products to global customers.

Request a Quote

Introduction — Why Choose a Chinese Tarpaulin Manufacturer?

China is a global hub for coated fabrics and tarpaulin manufacturing due to its integrated supply chain, advanced production equipment, and large-scale extrusion, coating and lamination capacity. Choosing a tarpaulin manufacturer in China like DER New Material offers economical factory-direct pricing, flexible OEM/ODM services, fast sample turnaround and the ability to scale from prototype runs to full container orders. DER’s experience enables product optimization for specific markets (e.g., EU, North America, Oceania) with tailored certificates and export documentation.

The best manufacturers combine material science (proper PVC formulas or PE lamination), robust base cloth selection (300D – 1000D polyester, HDPE woven), surface finishes (glossy, matte, lacquered, anti-slip) and finishing capabilities (welding, sewing, reinforced hems, printed logos). DER covers all these aspects with strict in-house quality control.

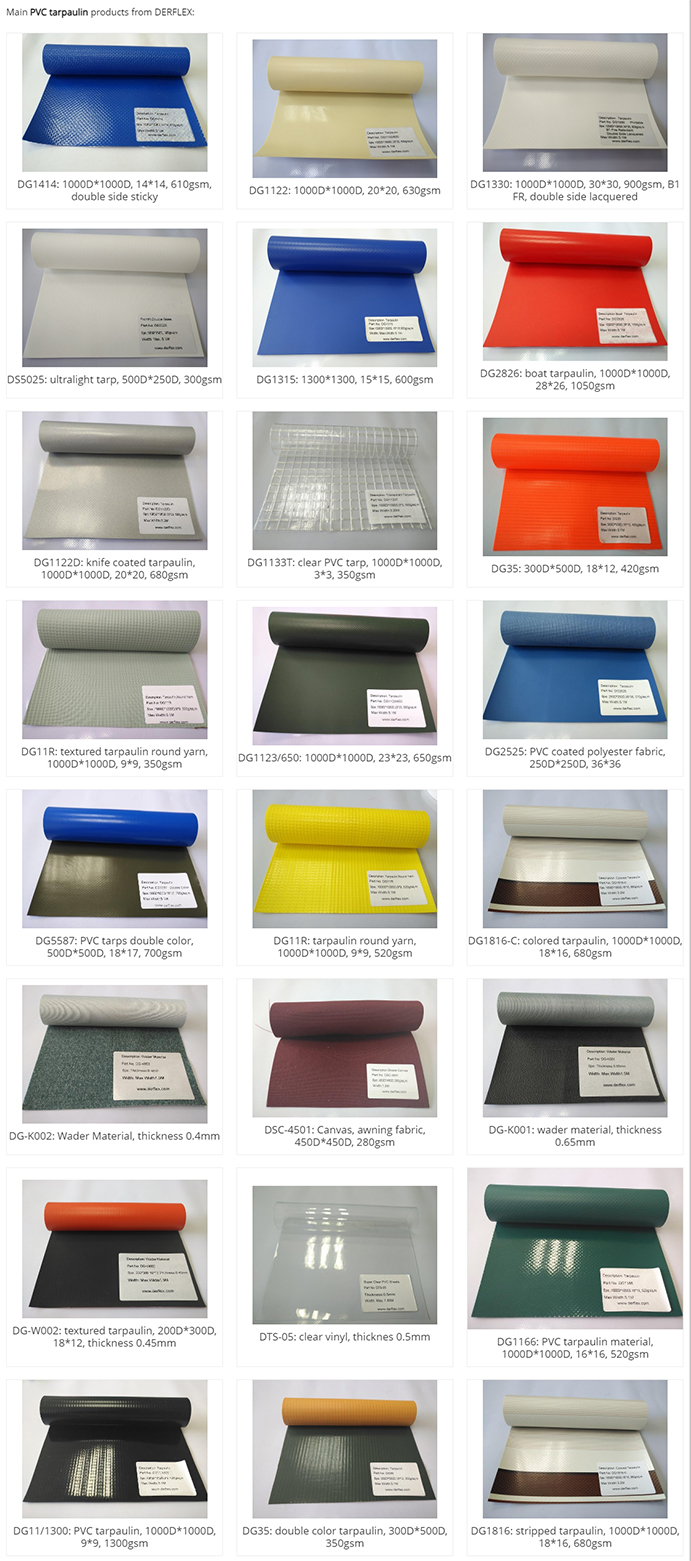

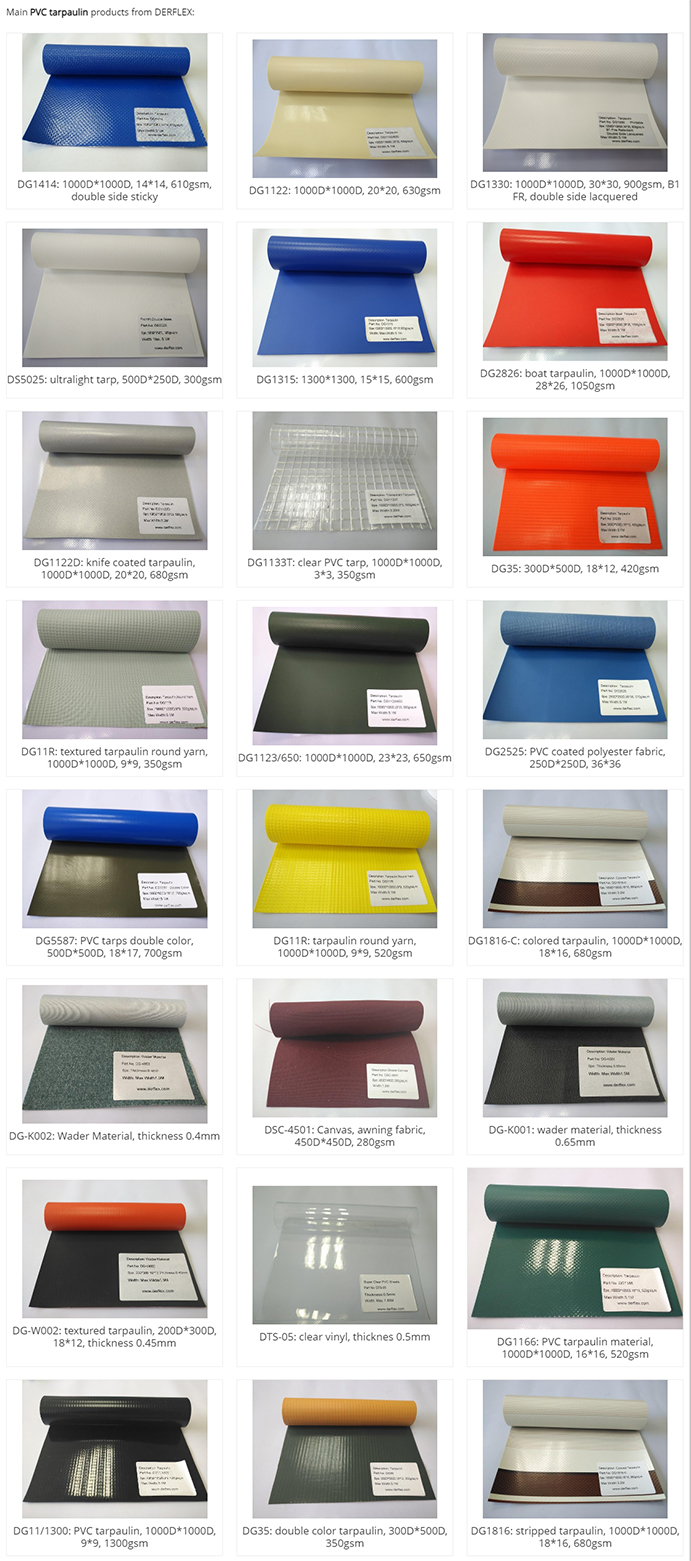

Product Introduction — DER Tarpaulin Ranges

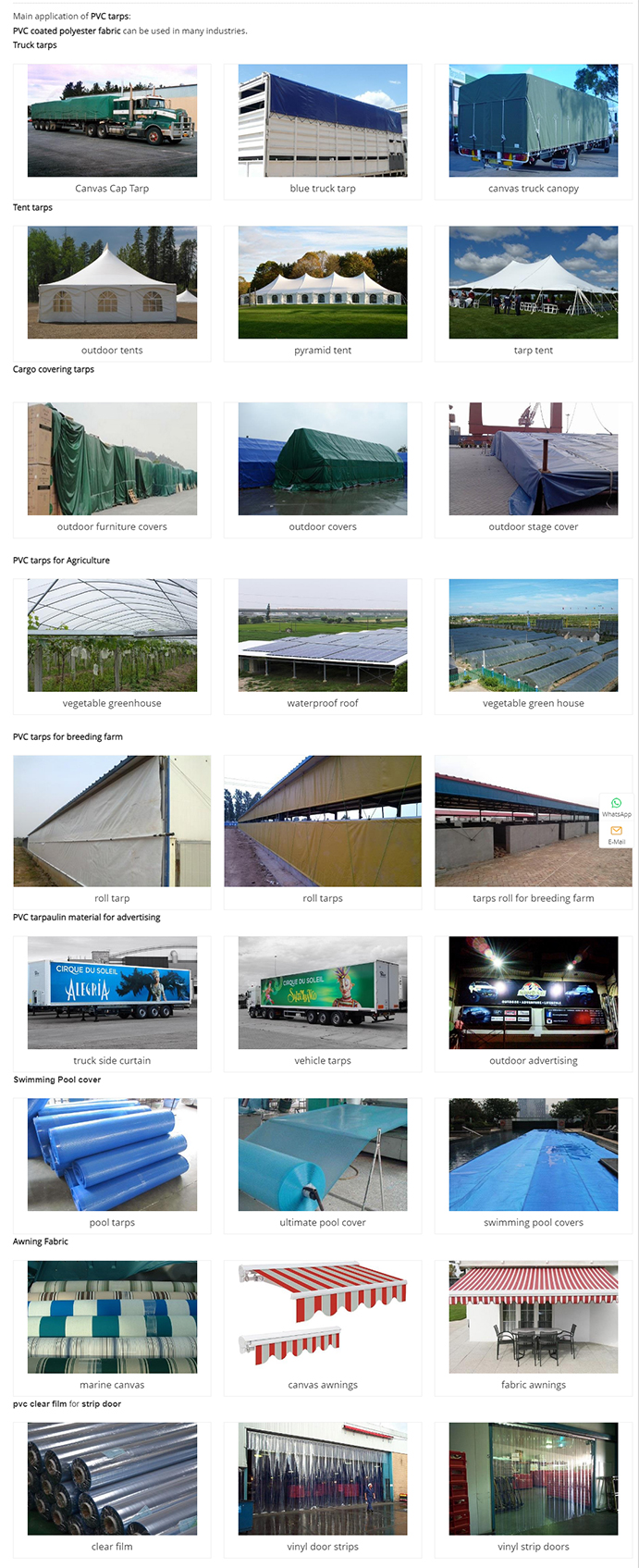

DER supplies a broad portfolio of tarpaulin products designed for multiple industries and use cases. Our main product families include:

-

PVC Coated Tarpaulins: Double-side PVC coated polyester fabrics for heavy-duty, long-life applications — used for truck covers, boat covers, industrial curtains and heavy-duty shelters.

-

PE Laminated Tarps: Economical laminated HDPE / LDPE products for light-to-medium duty uses such as temporary covers, garden tarps and budget container liners.

-

Silage & Agriculture Films: Multi-layer oxygen-barrier films and heavy PVC silage tarpaulins for forage preservation and farm storage protection.

-

Tent & Canopy Fabrics: Flame-retardant (optional) coated fabrics for event tents, military shelters, and marquees with printed branding options.

-

Industrial Curtains & Partitions: Welded PVC partitions and anti-dust curtains for warehouses and manufacturing plants.

-

Custom Fabrications: Cut-to-size tarps, welded pockets, reinforced hems, printed artwork and assemblies for OEM customers.

Every product line is available in multiple weights, widths and finishes to match the application requirements and budget constraints of buyers worldwide.

Product Features — What Sets DER Tarpaulins Apart

High-performing tarpaulins require attention to raw materials and manufacturing process. DER’s tarpaulin features include:

-

Material Quality: High-tenacity polyester base cloth or woven HDPE base; premium PVC resin or LDPE/MDPE lamination for balanced flexibility and strength.

-

Waterproof Integrity: Uniform coating and heat-welded seams ensure no leakage even under heavy rain.

-

UV & Weather Resistance: UV stabilizers and anti-aging additives reduce degradation and color fade in sun-exposed uses.

-

High Tensile & Tear Strength: Engineered fabric structure prevents tearing under load or wind stress.

-

Custom Finishes: Lacquered gloss, matte, anti-slip, anti-condensation, and food-grade coatings upon request.

-

Precision Finishing: CNC cutting, ultrasonic or hot-wedge welding, reinforced hems, and fitted accessories (grommets, webbing, D-rings).

-

Printing Capability: Digital and rotogravure printing up to 6 colours for branding, instructions, or safety markings.

-

Fire Retardant Options: Materials treated and tested to NFPA701, DIN4102 B1 or local standards for event and industrial safety.

Specifications — Typical Technical Data

Below are representative specifications used by DER across popular tarpaulin SKUs. Exact ranges are customizable per order.

|

Parameter

|

Typical Range / Options

|

|

Base Cloth

|

Polyester 300D / 500D / 1000D; HDPE woven for PE tarps

|

|

Coating / Lamination

|

Single/double PVC coating; LDPE lamination; multi-layer silage film

|

|

Weight

|

300gsm – 1200gsm (common: 400gsm, 550gsm, 650gsm)

|

|

Thickness

|

0.25mm – 1.2mm

|

|

Widths

|

1.02m, 1.5m, 2.0m, up to 5.10m continuous roll

|

|

Surface Finish

|

Glossy, matte, lacquered, anti-slip

|

|

Temperature Range

|

-40°C to +80°C (material dependent)

|

|

Seam Type

|

Hot-wedge welding, high-frequency welding, sewn with taped seam

|

|

Fittings

|

Brass / stainless grommets, rope hem, webbing, corner plates

|

|

Fire Rating

|

NFPA 701, DIN 4102, BS standards (on request)

|

|

Packaging

|

Rolls, folded bales, custom cartons, palletized for export

|

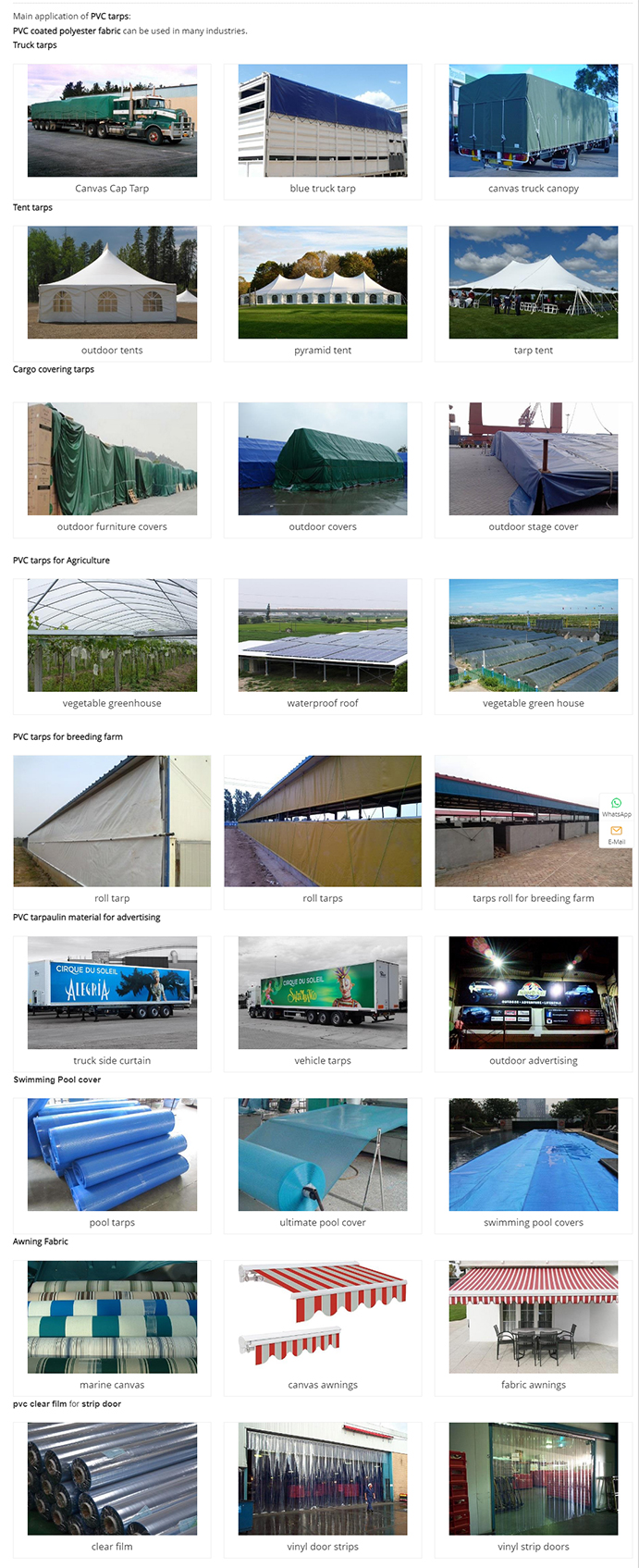

Product Applications — Industry Use Cases

DER tarpaulins are engineered for a wide range of industries. Below are common applications and recommended product choices:

-

Transportation & Logistics: Truck tarpaulins, curtain side covers, flatbed tarps and container liners (PVC heavy-duty tarps recommended).

-

Marine & Boating: Boat covers, dock and yacht protection (UV-treated PVC recommended for saltwater resistance).

-

Construction: Scaffold sheeting, temporary roofing, debris containment and ground protection (flame-retardant and heavy-duty PVC options).

-

Events & Tents: Event marquees, stage backdrops, and exhibition tents needing flame-retardant certification and printable surfaces.

-

Agriculture: Silage film, bale covers, greenhouse membranes and pond liners (PE and specialized oxygen-barrier films).

-

Industrial: Warehouse curtains, machine covers, dust partitions and custom protective covers.

-

Retail & OEM: Branded printed tarps for advertising, awnings and promotional canopies.

DER New Material — Company Profile

Company Name: DER New Material Co., Ltd (Der / DERFLEX)

Website: http://www.der-factory.com/en/

DER is a leading tarpaulin manufacturer in China with more than two decades of experience in coated fabric manufacturing. We run modern coating, lamination, printing and welding lines and maintain an experienced R&D team to refine material formulas and finishing processes. DER supports OEM/ODM programs, offers fast sample development and conducts strict quality inspections before shipment.

Certificates & Quality Assurance

To support global customers and specifiers, DER issues the following certificates and test reports upon request:

-

ISO 9001 — Quality Management System

-

SGS Test Reports — Tensile strength, tear resistance, hydrostatic head, UV ageing

-

NFPA 701 / DIN 4102 B1 / BS 7837 — Fire retardant testing (for applicable lines)

-

REACH & RoHS compliance documentation for restricted substances

-

Food-grade / non-toxic certificates for feed-contact or food-processing covers (on request)

We provide batch-specific test reports for large orders to ensure traceability and confidence in product performance.

Why Choose DER — Key Advantages

-

Factory Direct: Competitive pricing from an established manufacturer with transparent production costs.

-

Customization: Full OEM/ODM services — sizes, weights, colors, printing, fittings and packaging tailored to your brand and logistics.

-

Production Capacity: Scalable capacity to handle single prototypes, midsize orders, and full container shipments.

-

Technical Service: Sample support, CAD layout assistance, installation guidance and after-sales service.

-

Quality Control: Inline and end-of-line inspections, lab testing and certificate support for regulatory markets.

-

Export Experience: Expertise in shipping, HS codes, export packing and documentation for timely deliveries to global ports.

Installation Precautions & Best Practices

Proper installation prolongs service life and improves safety. Here are DER’s recommended precautions:

-

Assess substrate: Ensure the surface where the tarpaulin will be fixed is clean and free of sharp objects.

-

Correct anchoring: Use rope hems, evenly spaced grommets and distributed anchor points to prevent localized stress.

-

Seam strategy: For permanent or semi-permanent covers, use welded seams or overlap and tape methods recommended for the material.

-

Avoid over-tensioning: Overtightening can cause seam opening and stress tears, particularly in cold temperatures.

-

Check drainage: Angle large covers so water drains and does not pool on the surface.

-

Routine inspection: Periodically inspect grommets, sewn edges and welds; repair small punctures with patches or welding before they enlarge.

-

Storage: Clean, dry and roll tarps for long-term storage in a cool, shaded place to avoid UV and mildew damage.

Sold To — Global Markets & Export Footprint

DER exports tarpaulin products globally and supports customers in diverse markets. Representative export regions include:

-

North America: United States, Canada, Mexico

-

Europe: UK, Germany, France, Italy, Netherlands, Spain

-

Oceania: Australia, New Zealand

-

Asia & Middle East: Japan, South Korea, UAE, Saudi Arabia, India

-

Africa & Latin America: South Africa, Brazil, Chile, Egypt

We work with distributors, OEM partners, project contractors and government purchasers — providing export documentation and compliance certificates as required by each market.

Use Cases & Case Studies

DER’s tarpaulins have been used in many successful projects. A few real-world examples:

-

Logistics Fleet Rollout: A European distributor replaced heterogeneous covers with DER’s standardized truck tarpaulins — improving color consistency, reducing returns and lowering total landed cost.

-

Event Tent Program: An event company ordered flame-retardant PVC tents with printed branding and custom fittings for multiple venues — DER supplied samples and passed testing to NFPA standards.

-

Silage Preservation: A farming cooperative adopted DER oxygen-barrier silage films with welded seams and ballast systems — achieving better forage preservation and lower spoilage rates.

Relevant Keywords — SEO & Buyer Intent

To help buyers find the right products, this page targets these relevant long-tail keywords and search intents:

-

tarpaulin manufacturer China

-

PVC tarpaulin supplier

-

PE tarpaulin factory

-

custom tarps China OEM

-

heavy duty tarpaulin manufacturer

-

truck tarpaulin supplier

-

silage cover film supplier

-

flame retardant tent fabric

-

printed tarpaulin manufacturer

Frequently Asked Questions (FAQs)

What makes DER a reliable tarpaulin manufacturer in China?

DER offers integrated production (coating, lamination, printing, welding), strict QC, OEM customization, certification support and global logistics — combining decades of experience to ensure product consistency and timely delivery.

Can you supply tarpaulins with fire retardant certification?

Yes — we offer flame-retardant PVC fabrics tested to NFPA 701, DIN 4102 and other standards on request. Please specify the required certification during inquiry so we can match the right product and testing lab.

What is your typical lead time for custom tarpaulin orders?

Lead time depends on complexity: simple cut-and-hem orders can be shipped in 7–14 days; printed or highly customized welded assemblies typically take 2–6 weeks. Bulk and repeat orders follow agreed production schedules.

Do you provide samples before mass production?

Yes — DER provides material swatches and small physical samples. For printed or assembled prototypes we offer sample charges which are refundable on larger orders.

How do I place an order or request a quotation?

Use our website contact form or email sales@der-factory.com (or visit DER New Material) with your specifications: material, weight, size, quantity, required fittings and destination port. We’ll return a formal quote and sample options promptly.

DER New Material Co., Ltd. — Tarpaulin manufacturer in China

Website: http://www.der-factory.com/en/

Suggested URL for this page: http://www.der-factory.com/en/tarpaulin-manufacturer-china.html